Full-immersed cloth rotary filter

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

Full-immersed cloth rotary filter

Category:

Purpose

External-inlet internal-outlet rotary filter consists of a series of horizontally mounted rotary disc.Each fiter disc is combined by uniformfan-shaped flter plates. Detachable filter cloth is fitted on rotary disc which made of fiber and with filtration slot size of 10um.

There are three phases for fiber rotary filter pool: filtration, backwashing and sludge draining.

(1) Filtration

Sewage gravity flow enters into filter pool from outside of the flter cloth. Weir is set in the filter pool.The filtered wate

is accumulated

through hollow tube and the gravity flow discharge out of the filter pool through weir. The whole process is continuous.

(2)Rinsing

Partial sludge is accumulated on lateral of the filter cloth and then a sludge layer is formed. With the accumulation of sludge on fitercloth, the filtration resistance increases, so as the water levelof fler pool. Pressure sensor is set to detect the variation of water levelof fiterpool.PLC starts the anti-suction pump and rinse when the water level of fiter pool reaches the preset value. The fiter pool runs continuouslywhen rinsing.During filtration, the fiter disc keeps static to help the sludge deposition. During rinsing, the fiter disc rotates in speed of1rev/2minutes. The suction pump suck off the sludge particles adhered on the fiter cloth in negative pressure, and then the water in firationdisc is sucked from inside to outside, thus backwash the filter cloth. Instantaneous rinsing area is just 1% of the whole flter disc and thebackwash process is intermittent.

Two filter disc runs as a group when rinsing. By shifting the electric valve of suction pump pipe automatically, each rinsing group worksalternatively, while the suction pump runs continuously. When sudden inlet deterioration happens, the water level rising rapidly to backwashlevel, and meanwhile start every backwash pump to backwash the flter disc until the backwash period returns to normal state.

(3)Sludge discharging system

Abucket-shaped bottom is set under the fiter disc of the fiber rotary filter pool so as to accumulate the sludge.Bottom sludge depositionreduces sludge on fiter cloth, prolongs filiration time and decreases water consumption of backwash. After a setled time,PLC starts thesludge discharging pump and takes the sludge back to plant discharging system through piercing sludge discharging pump. During theworking period, the sludge discharging frequency and lasting time can be adjusted.

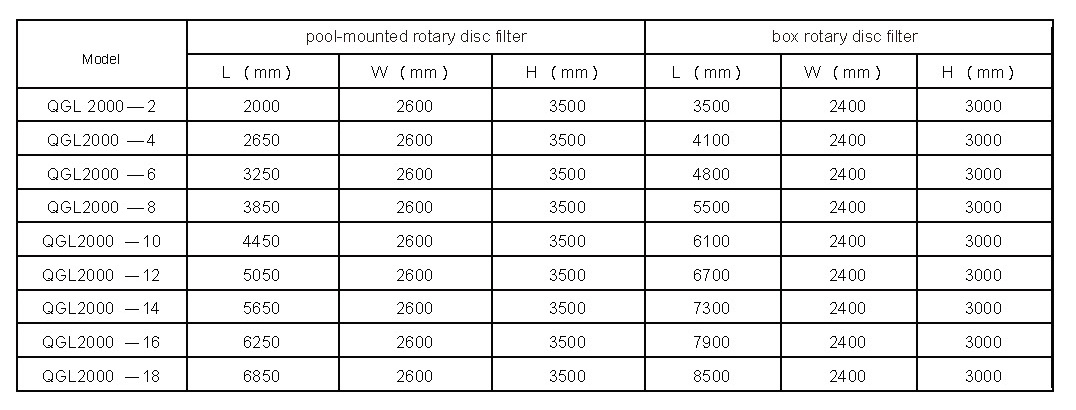

Outline dimension

Outline and installation dimension

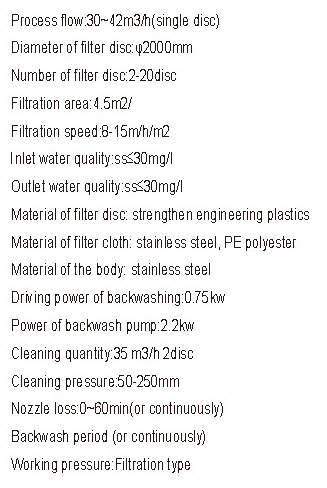

QGL 2000 technical parameter

Previous

Recommended products

Product Consultation