Semi-immersed cloth rotary filter

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

Semi-immersed cloth rotary filter

Category:

Introduction

Cloth rotary fiter is one of the most advanced filters all over the world. Currently, there are 700 sewage treatment plants take thistechnology. lt has advantages of effective filtration, high quality of output water, and stable operation.It has procured the unique waterreuse certificate—Title22 recognized internationally.

Purpose

Cloth rotary filter is mainly used for cooling circulation water treatment,sewage reuse after deep treatment. Reuse as cooling water or circulatingwater after filtration: inlet water quality sS<80mg/L, outlet water quality ss≤20mg/L. lt is used in sewage treatment.After being set in conventionalactivated sludge process, extended aeration,SBR device,oxidation ditchunit,trickling filter system and oxidation pool system, it can be applied infollowing areas:

1、removal of stubborn suspended solid.

2、phosphorusremoval by dosing.

3、removal of heavy metal. Cloth rotary filter is used forwater filtration of activated sludge sedimentation tank and water qualitydesigning is as follows: inlet SS:30mg/L(maximum:80-100mg/L), outlet Ss≤5mg/L,turbidity≤2NTU.The water quality is much better during actualoperation with turbidity about 1.

Working principle

Raw water filtration and backwash sludge discharging goes relatively independent andsimultaneously which are the two main processes of cloth rotary filter. This two mainprocesses are completed in different positions of the same filter.

a、 Raw water filtration: Sewage flows into rotary central cylinder of the filter due togravity. Square holes are set on the rotary central cylinder. Sewage flows into rotary centralcylinder through square holes and then enters into each filter liner. The floating solid insewage is trapped at inner of the filter disc and then the filtered water is discharged due tooverflow catchment.The filter device keeps static when filtering.

b、Backwash: Sludge is accumulated on inner of the filter cloth, thus form a sludgelayer gradually. With the accumulation of sludge on filter cloth,resistance of filtrationincreases, so does the water level of filtration pool. When the water level reaches thehigh-level, backwashing process is generated: driven by rotation of central cylinder,thereducer rotates with speed of 1-3revlminute, and the backwash pump works.After decimationof filtered water, the backwash pump flushes the filter cloth fitted on top from outside to insidethrough the hyperbaric umbrella injector fitted on the top of filter disc.The sludge on surfacewill be cleared and drained through draining pipe.The cleaning nozzle is movable up anddown. The filter cloth is easy to clean and water consumption is low.Frequency and durationof backwash are adjustable.The filter pool may run continuously when backwashing.

Main characteristics

1、Continuously operate for 24h without stopping the device. Continuous filtration can be going with backwashing.

2、Good effect. Slot size of filter cloth is 10um which may trap particles with size less than10um.The stability and quality of outletwater can be guaranteed.

3、Low water consumption for backwashing.Water consumption of backwashing is 1%-2% of total inlet quantity which is far lowerthan the other device.

4、Little loss of nozzle which is 0.05-0.25m.

5、Low operation cost.(regardless of agent cost for phosphorus) operation cost is lower than 0.01yuan/t.6.Low installation power.

7、Operate automatically. Filtration and backwashing are all controled by programs, and multiple protectionsare set so that there is noneed for special attention.

8、Small area coverage. Vertical design is applied in rotary filter so that small area coverage can meet the large-scale filtration.

9,Short time consumption. lt takes overall modular designing which is easy to facilitate and expansion.

Main technical parameter and installation dimension

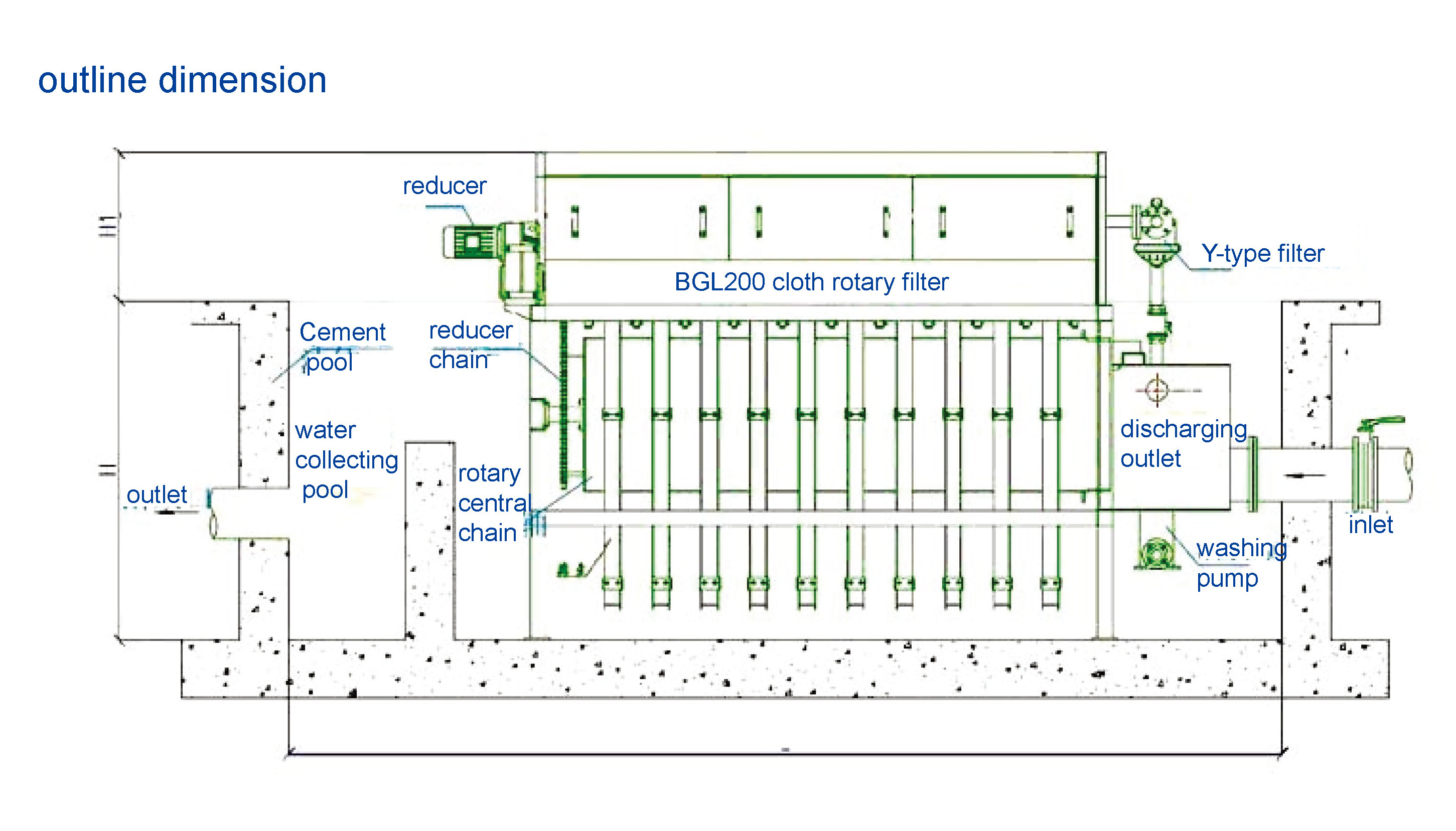

Outline and installation dimension

BGL2000 technical parameter

Process flow:28~35m3/h (single disc)

Diameter of filter disc: dp2000mm

Number of filter disc:3—23

Filtration area: 4.5m2/

Filtration speed:8—15m/h/m2

lnlet water quality:SSs30mg/L

Outlet water quality:SSs10mg/L

Material of filter disc: strengthen engineering plastics

Material of filter cloth: stainless steel, PE polyester

Material of the body: stainless steel

Driving power of backwashing: 1.5KW

Power of backwash pump:5-11KW

Cleaning quantity:30L/1/1

Cleaning pressure: 6-8bar

Nozzle loss:50-200mm

Backwash period:1-3min (or continuously)

Working: pressure (or continuously)

Filtration type

Previous

Next

Recommended products

Product Consultation