DYQ belt concentration & dewatering integrator

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

DYQ belt concentration & dewatering integrator

Purpose

DYQ belt concentration and dewatering integratr is mainly usec to contentrate and dewater the residual sudge mixed studge through biochemicaltreatmentof municipal sewagae.lt is high-efficiency dewatering facility forming the sudge as cake. is appicable to sludge dewalering n all ields such as water supply &drainage, papermaking, casting, leather , textile, chemical and foodstuff etc.

DNT elt concentration and dewatering integrator is mainly used to contentrate and dewaterthe residual sudge mixed sudge through biochemical reatmentof municipal sewagae .lti igh-eficiency dewatering facility forming the sludge as cake. t is appicable to sludge dewatering i al felds such as water supply &drainage, papermaking, casting, leather , textile, chemical and foodstuff etc.

Structure & workina principle

This equipment consists of belt concentrator and dewaterer. The sludge is mixed and reacted suficienty in the sudge mixer anter the focculan is added.Afterwards,the sludge fows into the gravity dewatering section.Alot ofree water in the sludge flows ou of the gap of fiter elt under the acion of gravity andthe free water enters into the water collection tank.Afenwards,it is guided by wedge precompression seacion so that the sudge is leveled graduly and t sdewatered further afer slight squeezing. Then, the sludge enters nto S-shape multi-vll queezing section and it is clamped in the micdle bebween upper layer offiter cloth and lower layer of fiter cloth.The sludge is squeezed repeatedly by several ros n iferent diameters. As thi time,the sludge is sheared to faciiatethe sudge to dewater further to form the cake. Final y,the scraper is used to scrape down the cake and transport out the cake.The upper and lower fiter bet anbe reused after washing.

Model explanationo

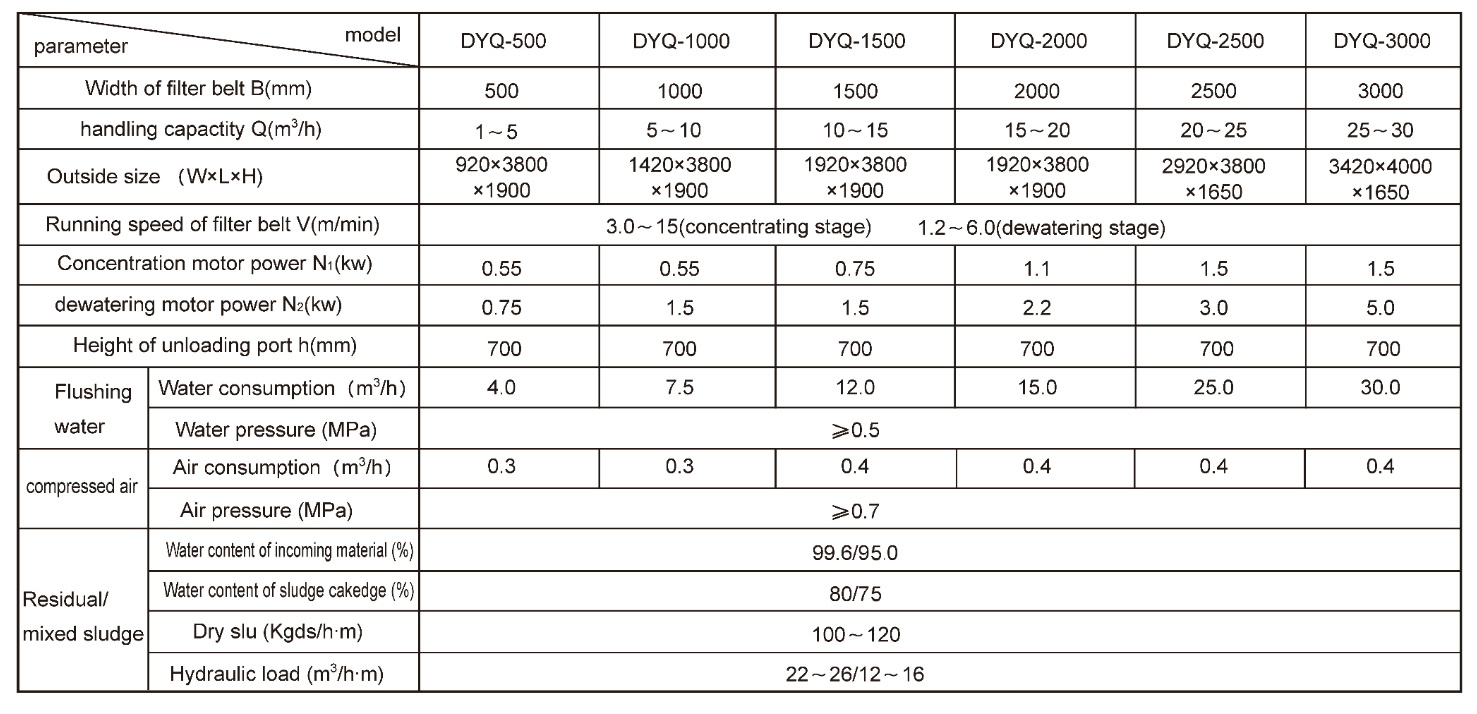

Main technical parameter & installation dimension form

Main feature

1.Stepless regulating motor drive can regulate the running speed at any time and it has strong adaptablility

2.The specially-made flushing nozzle and clogging -prevention device will flush off the filter belt.

3.The T-shape water leakage groove is used in the dewatering head roll to squeeze off the water to flow out quickly.

4.The gravity dewatering section is of inclined design. The static head of sludge is enlarged to enhance the dewatering effect so thatthe sludge can be thickened sufficiently before squeezing.

5.Compact structure of whole machine, automactic deviation rectfication of fiter belt, low operation noise, power consumption saving,

Outline & installation foundation drawing

Recommended products

Product Consultation