Disc spiral dewatering device

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

Disc spiral dewatering device

Introduction

Introducing Japanese technology, combined with Chinese sludge characteristics, anew sludge dewatering device-disc spiral dewatering device is launched which hasadvantages of no filtration cloth, no fouling, abrasion resistance as well as low energyconsumption. It resolves technical difficulties which the previous generation can't dealwith such as large floor area, refractory low concentration sludge and special oilysludge.

The solid-liquid separation device is composed by mutually movable static ring,swimming ring and spiral shaft and is divided into concentration part and dewateringpart.Sludge is dewatered in squeezed compression tank through spiral shaft,and thenthe water exuded out from the clearance of movable static ring and swimming ring. Theunique characteristic of this device is that the static ring moves driven by a specialdriving device of spiral shaft. No abrasion and friction is produced, thus extends thelifespan of the whole device greatly.

Structure

The core of spiral dewatering device is one or several groups filter consists ofspiral driving shaft, multiple fixed discs and multiple swimming discs.Each shaft isdivided into concentration part and dewatering part. From the sewage inlet of concen-tration part to sludge cake outlet of dewatering part, screw pitch of shaft becomessmaller, and the clearance between static ring and swimming ring also becomessmaller gradually. Back pressure plate of sludge outlet is set to adjust the pressure ofspiral cavity.With unique and subtle filter body, disc spiral sludge dewatering devicereplace the traditional cloth and centrifugal filtration by completing sludge concentrationand squeezing dewatering in a cylinder.

Working principle

Concentration: when the spiral driving shaft rotates, pushing the multi-laminatedsolid living disc move relatively, and then the water flows from the clearance of disc dueto the gravity, thus realizes rapid concentration.

Dewatering: when the spiral shaft rotates,sludge after concentration movesforward continuously.Along the outlet direction of sludge cake, screw pitch of spiralshaft becomes smaller,and the clearance among rings also becomes smaller, thus thevolume of spiral cavity shrinks continuously. The internal pressure increases graduallydue to the back pressure plate.The water in sludge is squeezed and discharged underthe continuous rotation of spiral driving shaft. Solid in filter cake increases continuouslyand realize continuous dewatering eventually.

Self-cleaning: the spiral shaft rotates, and drives the swimming shaft rotate.Thedevice realizes self-cleaning due to the move between static ring and swimming ring,thus prevent the dewatering device being blocked.

Engineering advantages

Reduce floor area: the sludge in aerator or secondary sedimentation pool can bedealt with directly without sludge concentration pool or storage pool.

Enhance the capacity of phosphorous removal.The sludge dewaters underaerobic condition so as to avoid phosphorus releasing under anoxic or anaerobiccondition, thus enhance the capacity of phosphorous removal.

Easy to operate and maintain. No filtration cloth, no filtration slot. Safe and simpleoperation.Combined with automatic dosing system, the device may realize 24h unattended operation.

Decrease processing load of the device.The integration treatment relieves theload of subsequent biochemical reactor.

Characteristics

1、Large coverage of sludge density which may from 2000mg/L to 50000mg/L.

2、Deal with oily sludge effectively.Easy to separate, not prone to be blocked.

3、Clean and environmental, no odor, no noise, no high-pressure washing, no secondary pollution.

4、Small olume, low water and energy consumption. Unit electricity is 0.1kwh/kgDS, unit water consumption is 0.03t/h.

5、Easy to maintain, available to operate continuously, unattended operation, unnecessary to change engine oil.

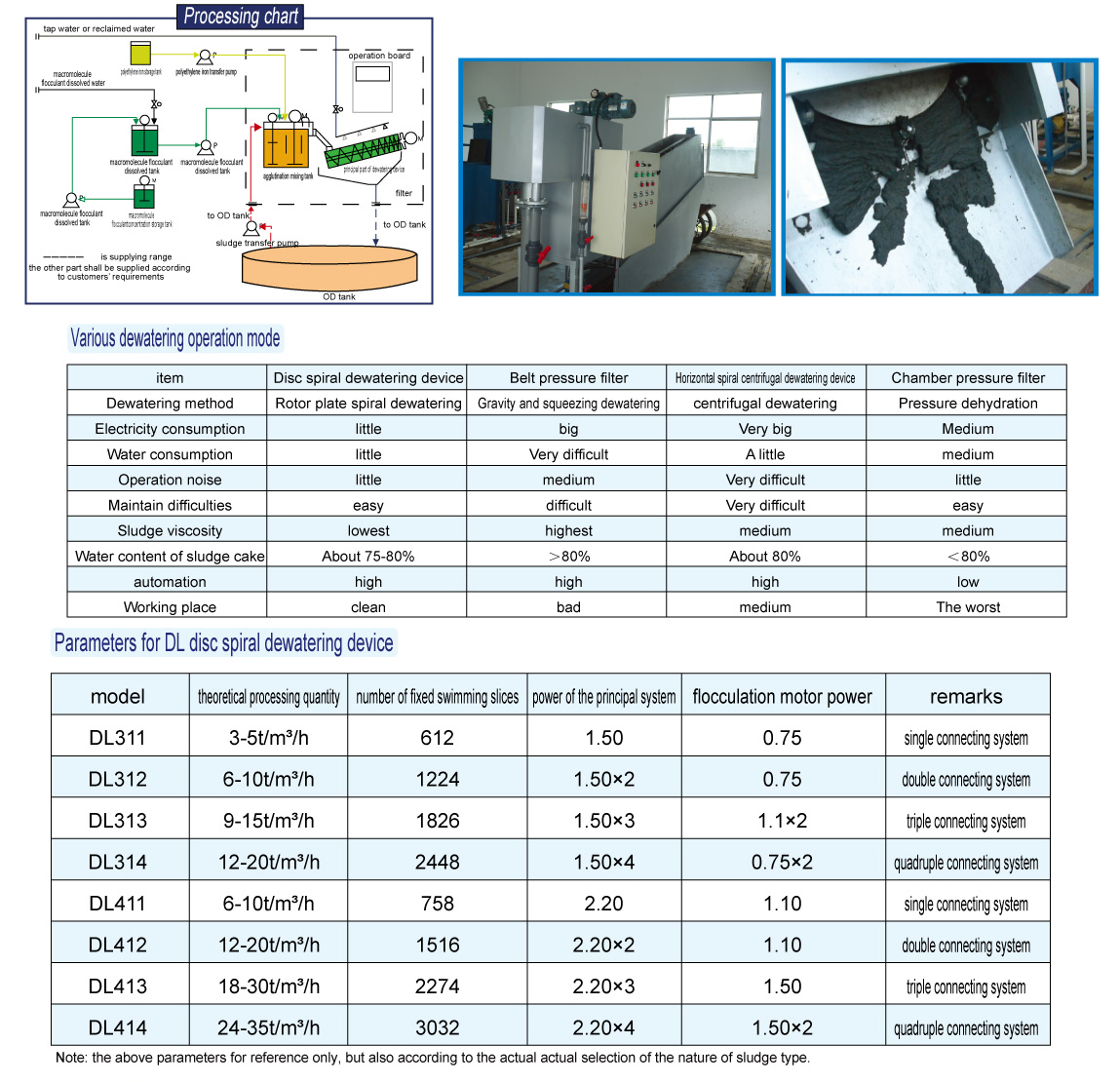

Processing chart

Recommended products

Product Consultation