DNT belt concentration & dewatering integrator

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

DNT belt concentration & dewatering integrator

Purpose

DNT belt concentration and dewatering integrator is mainly used to contentrate and dewater the residual sludge mixed sludge throughbiochemical treatment of municipal sewagae. t is high-efficiency dewatering facility foming the sludge as cake.lt is appicable to sludgedewatering in all fields such as water supply &drainage, papermaking, casting, leather , textile, chemical and foodstuff etc.

Structure & working principle

This equipment consists of belt concentrator and dewaterer.The sludge is mixed and reacted sufficiently in the sludge mixer after thefocculant is added.Aftewards, the sludge flows into the gravity dewaterning section. Alot of free water in the sludge flows out of the gap offiter belt under the action of gravity and the free water enters into the water collection tank.Aferwards, it is guided by wedge precompressionsection so that the sludge is leveled gradully and it is dewatered further after slight squeezing.Then, the sludge enters into S-shape multi-rolsqueezing section and it is clamped in the middle between upper layer of fiter cloth and lower layer of flter cloth. The sludge is squeezedrepeatedly by severalrolls in diferent diameters. As this time, the sludge is sheared to faciliate the sludge to dewater further to form the cake.Finally, the scraper is used to scrape down the cake and transport out the cake. The upper and lower filtet belt can be reused after washing.

Model explanationo

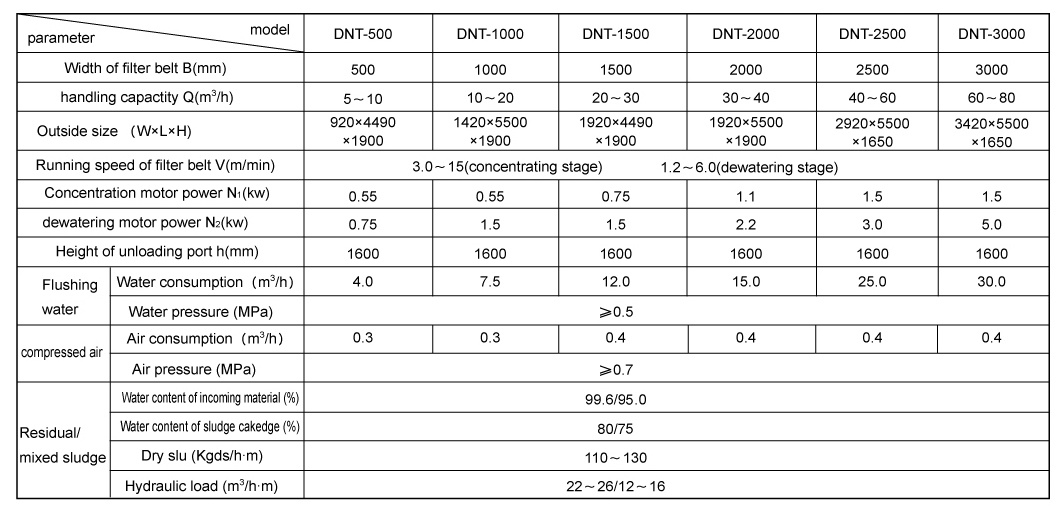

Main technical parameter &. installation dimension form

Main feature

1.Stepless regulating motor drive can regulate the running speed at any time and it has strong adaptablility2.The specially-made flushing nozzle and clogging -prevention device will flush off the filter belt.

3.The T-shape water leakage groove is used in the dewatering head roll to squeeze off the water to flow out quickly.

4.The gravity dewatering section is of indlined design.The static head of sludge is enlarged to enhance the dewatering effect so thatthe sludge can be thickened sufficiently before squeezing.

5.Compact structure of whole machine, automactic deviation rectification ofiter belt,low operation noise, power consumption saving,less chemicals consumption, good dewatering effect and low operation expense.

Next

Recommended products

Product Consultation