ZCG Suspended center- drive sludge scrapper

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

ZCG Suspended center- drive sludge scrapper

Purpose

ZCG suspended center-drive mud scrapper is applicable to the radial-fiow sedimentaton tank n large and medium as well as small tank diamer and withcentral in et and peripheral outetas well as sludge discharging. t i manly used for sludge discharge in the sedimentationtank in the town sewage treatment plantor industrial wastewater treatment engieneering.

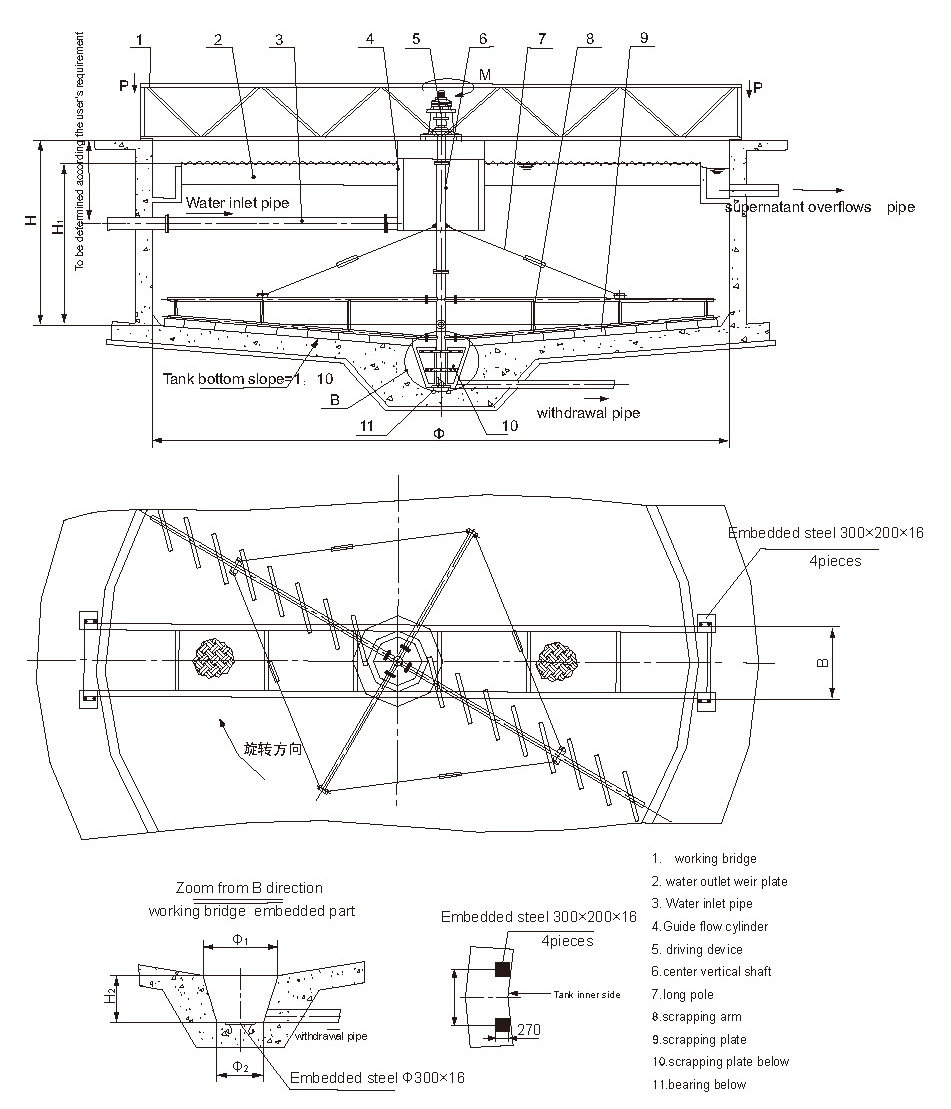

2、Structure & working principle

This equipment is of center drive and suspended type. T'he sewage fows in the guide fow cyIinder fromthe water inlet pipe beneath the working tridge anditflows out to the tank periphery uniformly in radia state ater t is dispersed. The sudge in suspended state i deposited at the tank bottom ater setling. The drveunit ir ves the center verical shaft to rotae and drives the scraping arm and sludge scraping plate to rotate sinutaneousy . Afer the sludge is scraped to thecentral sludge callecting chute from the tank peihey it s discharged out of tank dependig on the taic water pressure n the tank. Afitenw ads,the sudge isdischarged out of tank through central sudge withd awal pipe. The scum abov e the water suface is guided in the deslagged hopper by rotay skirrning devireand thenit is discharge out of tank. The supematant overflows in the efuent chute through the triangular effuent weir plate and it is discharged out.

Model explanation

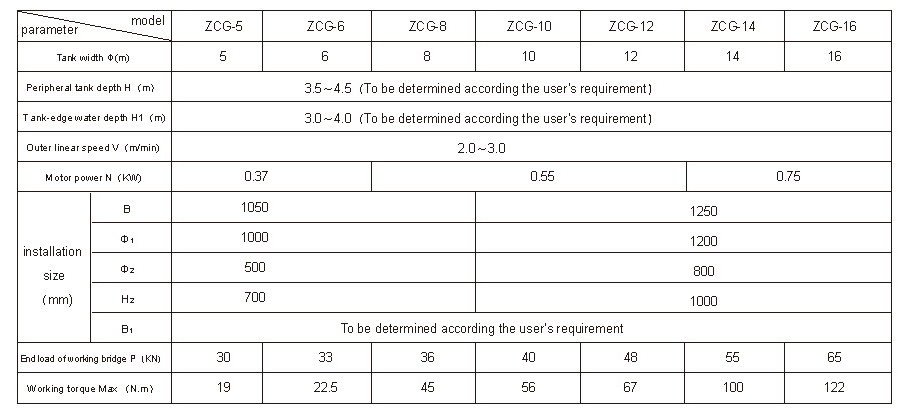

Main technical parameter & installation dimension form

Main feature

1.The working bridge is of ful- bridge type. ts material can be used carbon steel, stainless steel or concrete structure

2.For drie unt,the verical3-stage cyodordal pirwheel educer or comtinaton between the bev el gear reducer and worm gear reducer is adopted to assure theoutput torgue and rotational speed as well as high transmission effect.

3.For the scraping plate , the linear scraping plate is used.

4.The underwater bearing scraping kife is installed at the lower end of erical shaft of sludge scraper to prevent the verical shaft fom out beating whilerotatingand sludge from compaction in the sludge collecting chute.

5. Installation of the mechanical and electrical overload protection. Safe and reliable operation.

6.The equipment operation is simple and convenient and the localremotecontrol changeov er swtch is installed so that i can contodl the exipmert directly

Outline & installation foundation drawing

Recommended products

Product Consultation