ZBGX periphera-drive mud scrapper & suction dredge

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

ZBGX periphera-drive mud scrapper & suction dredge

Purpose

ZBGX peripheral-drive mud scrapper &. suction dredge can be applicable to the radial-flow sedimentation tank in large andmedium as well as tank diameter and with central nlet and peripheral outlet as well as central sludge discharging Itis mainly used forsludge suction and discharge in the secondary sedimentation tank in the town sewage treatment plant.

2、Structure & working principle

This peripheral drive is adopted for this equipment. The sewage flows in the tankform the water inlet pipe at the tank center and itfiows out to the tank periphery uniformly in radal state after it is dispersed by steady fiow cylinder. The sludge in suspended state isdeposited at the tank bottom after setting. The drive unt drives the working bridge to rotate along the tank periphery and drives thescraping arm and sludge scraping plate to rotate simultaneously. The sludge is suctioned into the sludge cllecting chute by sludgesudion pipe depending on he static water pressure in the tank and it is dscharged in the central sludge cylinder after it is scraped andcollected ty sludge scraping plate . Afterwards,the sludge is discharged out of the tank through the centrai sludge withdrawal pipe. Thescum above the water suface is guided in the deslagging hopper by rotating skiming device and it is dscharged out of tank Thesupernatant overflows in the effluent chute through the triangular effluent weir plate and it is discharged out.

Model explanation

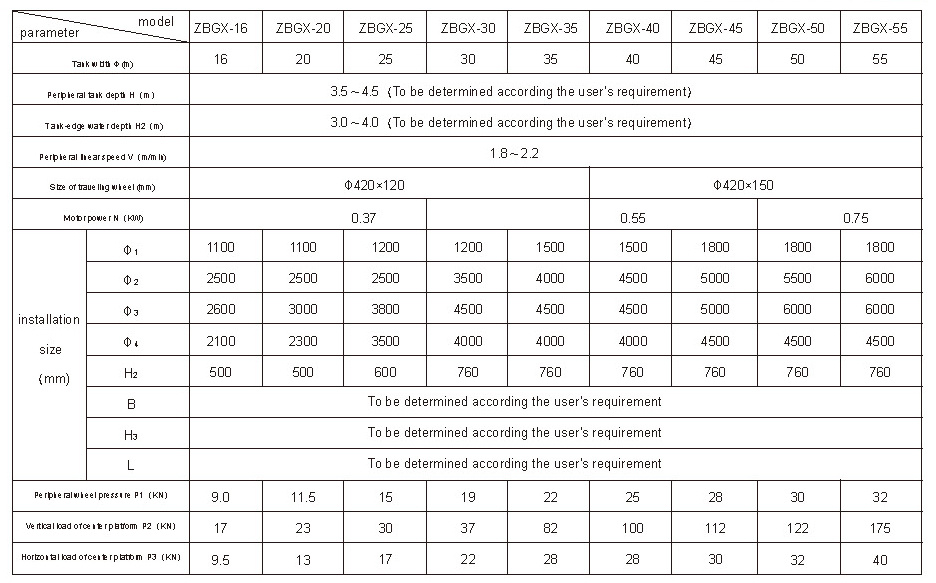

Main technical parameter & installation dim ension form

Main feature

1. The woking bridge can be either ha-bridge type or fullbridge type t can be made from carbon steel and stainless steel and aluminum alloy .etc.

2.Forthe drive unt,the axialyinstaled bevel gear reduoer s coupled directhy wth driving roler for drving, thas such adtrantages compact struture and high mechanical eficienoy and soon.

3.Thesludge suoio pipeis of hon mouth form withgd sudgesu.tonefet Aualabletwo sudge s ueio modes se ution and sihon sucton ( normally,the self-suction adopted)

Outline & installation foundation drawing

Recommended products

Product Consultation