ZBG Peripheral-driving mud scraper

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

ZBG Peripheral-driving mud scraper

Puroose

ZBG peripheral diving mud scaper can be applicable to the radial-flow sedimentaion tank in large and medium tank diameter with central inlet andperigheral outet as vell as cental sudge discharging.1t is mainly used for sudge discharge in the primanry sedimentation tank in the town sewage treatmentplant.For this equipment, the scientic and technological achievements promcton project cetficat issued by Ministy of Constuction was obtained in 2002 year

Structure & operating principle

The peripheral driving is adopted for this equipment. The sewage flows in thetank from the water inlet pipe at the tank center and it flows out to the tank peripheryuniformly in radial state after it is dispersed by steady flow cylinder. The sludge insuspended state is scraping at the tank bottom after settling. The drive unit drives theworking bridge to rotate along the tank periphery and drives the scrping arm andsludge scraping plate to rotate simultaneously. The sludge is suctioned into thesludge cylinder after it is scraped and collected by suldge scraping plate.

Afterwards, the sludge is discharged out of the tank trough the central sludgewithdrawal pipe.The scum above the water surface is skimmer to tank edge by rotaryskimming device and then the scum is scraped in the deslagging ho

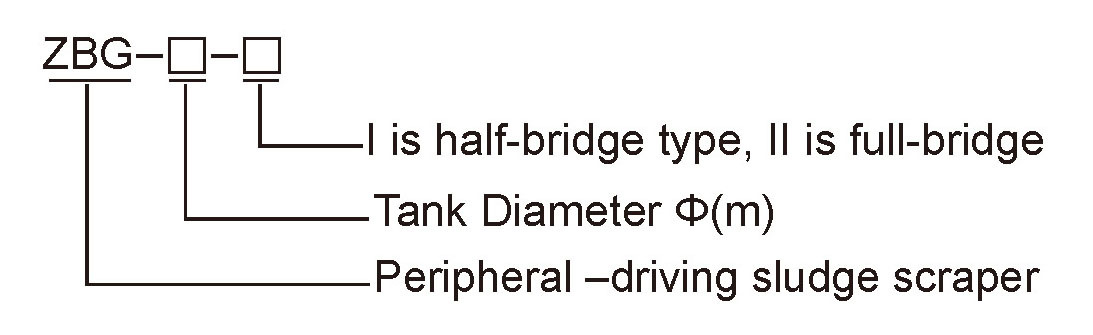

Model explanation

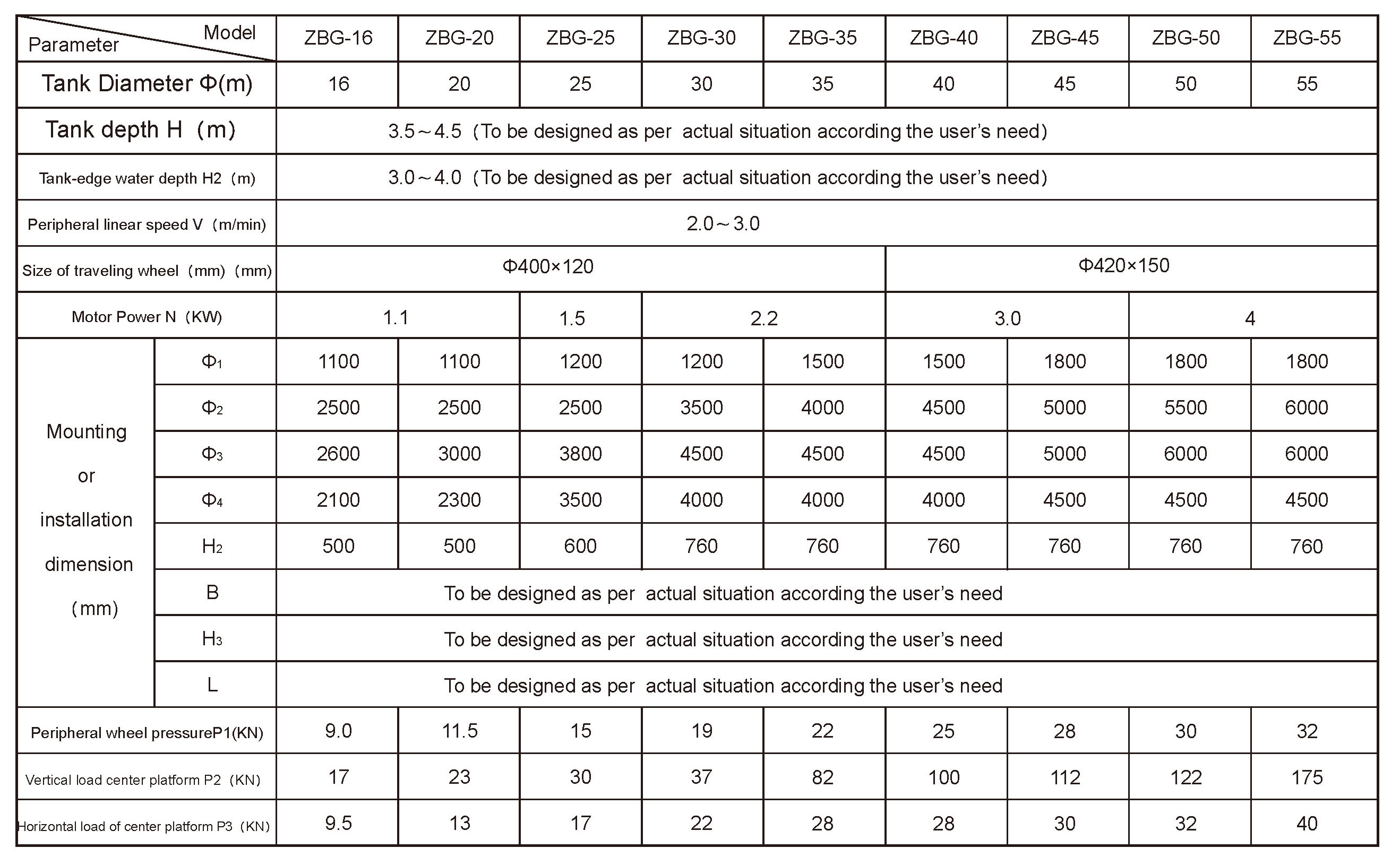

Main technical parameter & installation dimension form

Main feature

1.The working bridge can be either half-bridge type or ful-bridge type. lt can be made of carbon steel material and stair less steel and aluminium alloy etc.

2.Forthe bhving deric the aval y nstled bevel gear redoce is coupled dlifctlyroler ordiving t has such atvanlaes as compart stocure an high mecanical ef.ciency and so on

3.The scraping plate collecls the sludge in the trace of log spiral t has such advantages as good continuity and high sludge collection efficiency

4. When the slope of tank bottom is 1:10, the resistance while sludge scraping can be reduced.

5.The equipment operation is simple and convenient , and the local remote control changeover swich is insalld as tht it an control the equipment drectly

Outline & installation foundation drawing

Next

Recommended products

Product Consultation