LSF sand-water separator

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

LSF sand-water separator

Category:

Purpose

LSF sand-water separator is used for sand-water treatment in the grid chamber ltank in the town sewage treatment plant.lt ismainly used together with desander of cyclone grid chamber or bridge desander to separate the discharged sand-water mixed liquorfurther.

2、Structure & working principle

This equipment is of shaftless screw type. The sand-water mixed liquor is input from the upper part of separator. The gravel settles inthe sand-water separation groove depending on the gravity.The shaftiess helicoids rotate and push the gravel to the outet along U-shapedchute of 250 gradually.The gravel alls down in the charging barrel and then it is transported out.The separated water is discharged fromthe overflow port of separation groove to improve the operation environment and it is good for transportation out

Model explanation

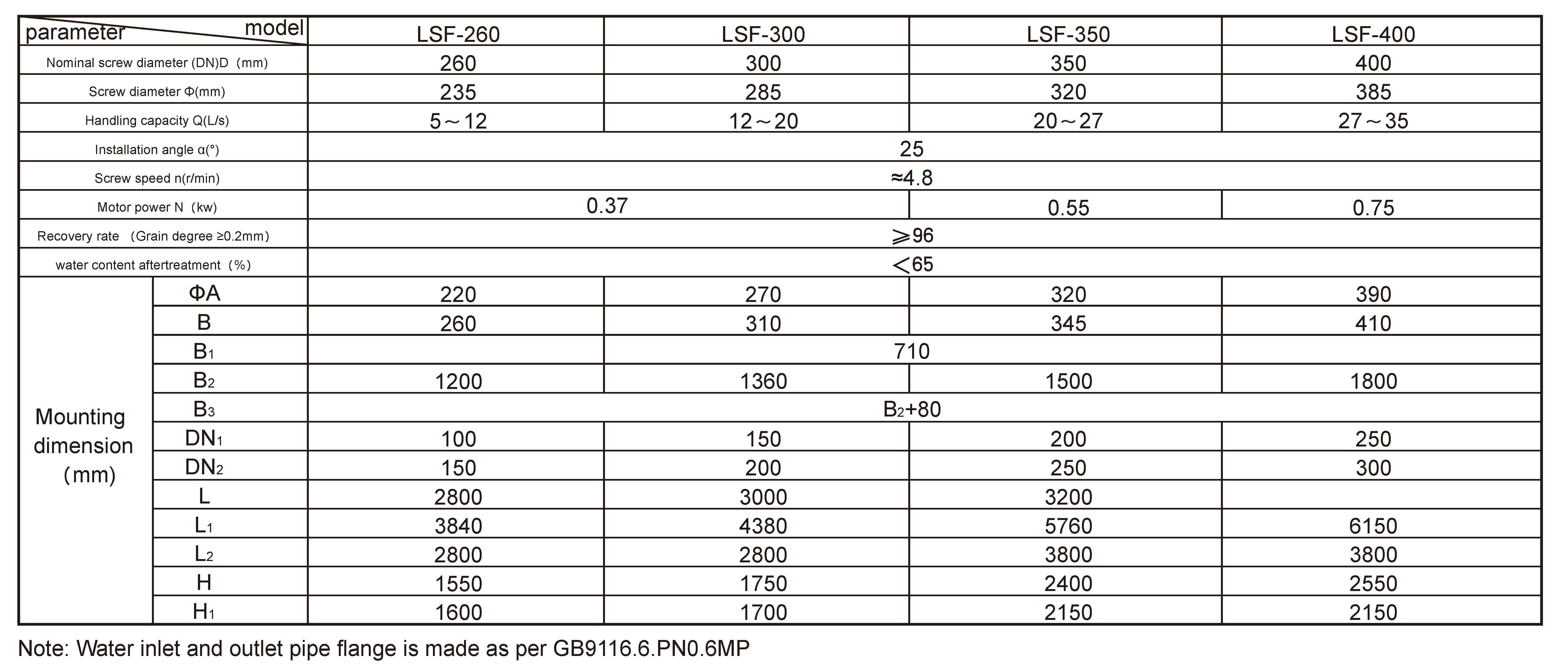

Main technical parameter & installation dimension form

Main fearture

1、For drive unit, the axely-ntalled parallel axis bevel-gear reducer is used.The structure is compact and the operation is safe and smooth.

2.The recovery rate of particle whose grain size is larger than 0.2mm can be up to 96% after separation.

3.The imerlner is intalled n the U-shaped chute and it has such advantages as strong wear-resiting propery and long senvice life as well as easy replacement.

4.For the whole machine,theflly encbosed operationis adopted.The enwironment condtionisgood. The framewr is fxed by the expansion bolt wthout embedded par.

Outline & installation foundation drawing

Previous

Recommended products

Product Consultation