XLC desander of cyclone grit chamber

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

XLC desander of cyclone grit chamber

Category:

Purpose

XLC desander of cyclone gritis mainly used in the cyclone grit chamber at the town sewage treatment plant and this equipment usesthe hydraulic rotational flow to separate the sand from organic substance effectively. lt is the ideal desanding equipment.

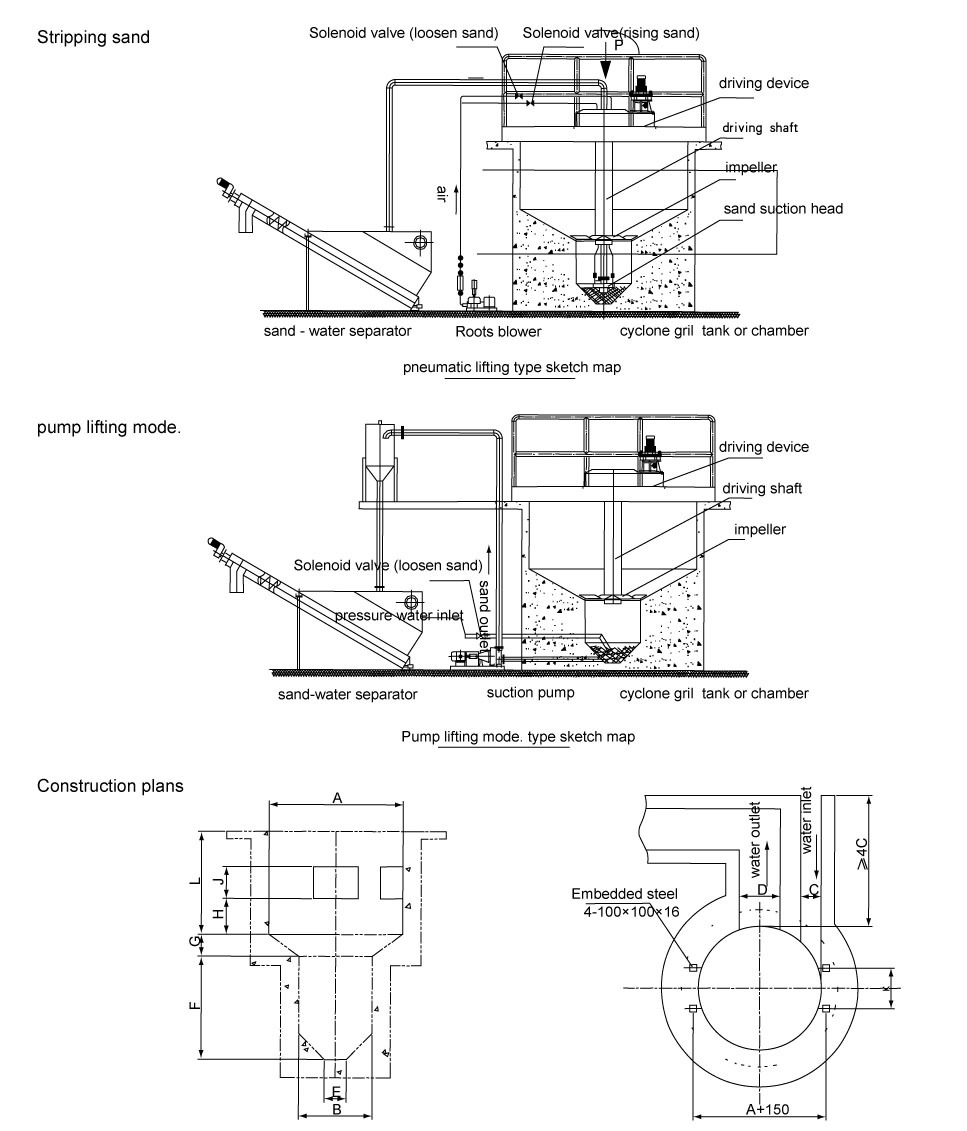

Structure & working principle

The cone-bottom round tank is used for cyclone grit chamber. The blade separator is installed inside the tank.The sewage flowsin the tank along the tangential direction and rotates by 270℃c(as per the clock-wise direction in top view).Afterwards, the sewage isdischarged from discharge channel and the certain flow velocity of water inlet is used as the dynamic power to carry out the tangentialmotion along the inner wall of round grt chamber to form the cyclone, at the same time, the propeller blade is agitated to facilitate theliquid cyclone and axial whir.Thus ,the setting of sand particle in the sewage is accelerated to separate the organic substance in thewater from sand particle effectively.The closer the water closes to the tank center,the smaller water flow section is and the water flowvelocty accelerates as well as bottom water flow velocity is increased centripetally. By using this principle ,the sand setled at the tankbottom moves to the central sand hopper by spiral trace and the organic substance lifts up at the tank center as well asit is dischargedout together with effiuent water flow. The sand settled at the bottom is lited up by lifing device and the sand water separation iscompleted after the sand enters into the sand-water separator. Afterwards ,the sewage flows into the screen well.

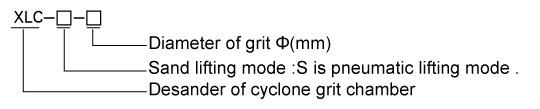

Model explanation

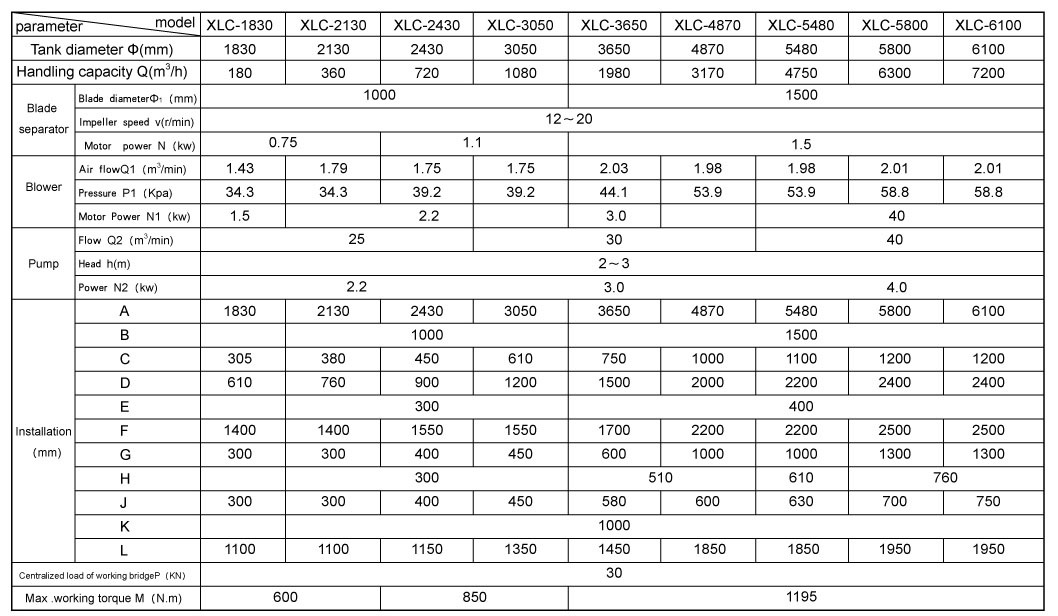

Main technical parameter & installation dimension form

Note

1.Hydraulic surface :200m3/m2.h;

2.Hydraulic retention time :20~30s;

3. Water inlet flow velocity:

V=0.6~0.9m/s when Q=Q max(40~80%),V>0.15m/s when Q=Q max

4.The inclination angle of inlet and outlet channel is not less than 270°c.

Main feature

Avalable in wo sand ifing modes. pneunatc lfing and punmplifting mode .The pneurmaic iting disposa efie isrelatively beter but the pumpig ifing costis elativly owe.

Good using effect. The removal rate of particle more than 0.2mm is more than 85%.

The tank can be made stee in case of disposal amount Q<1080m3/h. The tank is of concrete structure generally in case of Q21080m3h

The PLC is used in the system to control the sand washing sand washing and discharging period automatically and the system runs safely and reliably.

Outline & installation foundation drawing

Previous

Recommended products

Product Consultation