QXS bridge sand sucker

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

QXS bridge sand sucker

Category:

1、Purpose

QXS bridge sand sucker is mainly used for sand-water treatment of aerated grt chamberl tank in the town sewage treatment plantor waterworks to lit up the large particle and cinder and so on settled at the bottom in the sand discharging chute beside the tank. Theoil skimmer and slag skimmer can be added as per the user's requirement.

2、Structure & working principle

This equipment is of movable bridge and pumping type.When the sand sucker does not operate, it stops at the water inlet end.When the sand sucker operates, the crane lits down the skimming plate at the first under the instruction from electrical control while thesand sucker travels downstream to scrape and collect the scum and skim it in the steel-made skimming chute at the tank end.Whiletraveling in opposite direction,the skimming rake lits up and liquid level to prevent the scum from traveling in opposite direction The sandwater at the bottom of tank is drained in the sand collecting chute beside the tank by sand sucking pump through suction pip.Aftenwords, the sand and water flows in the sand-water separator through this pipe for further disposal. The back-and-forth operationmotion is carried out and thus the sand suction and discharging as well as skimming purpose is reached.

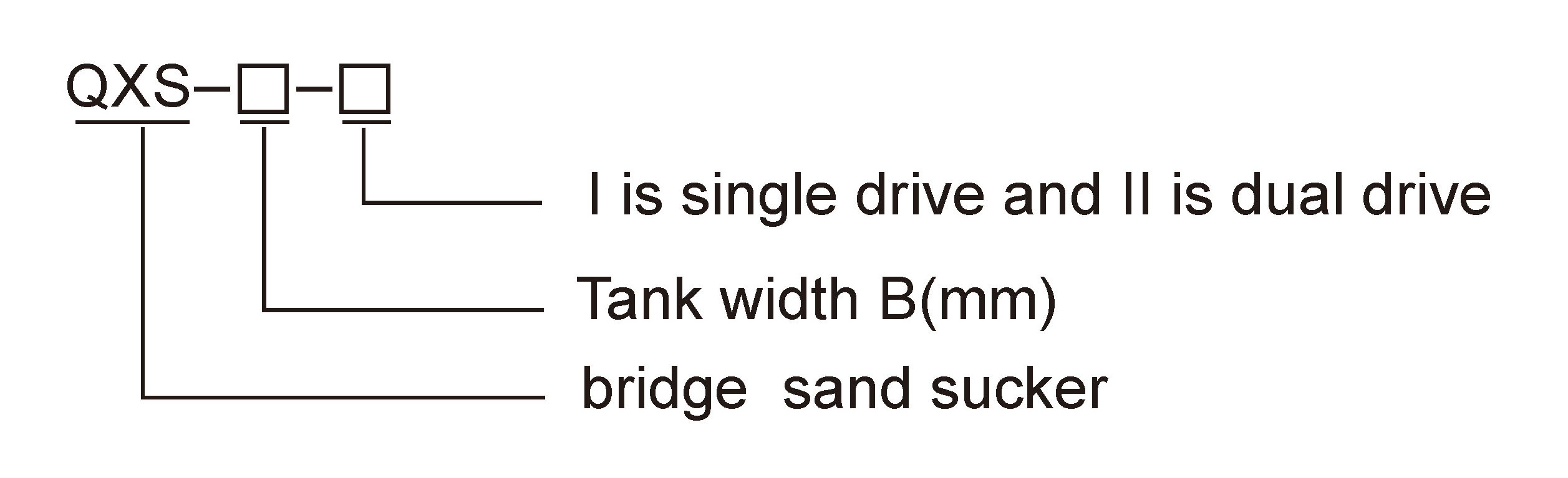

Model explanation

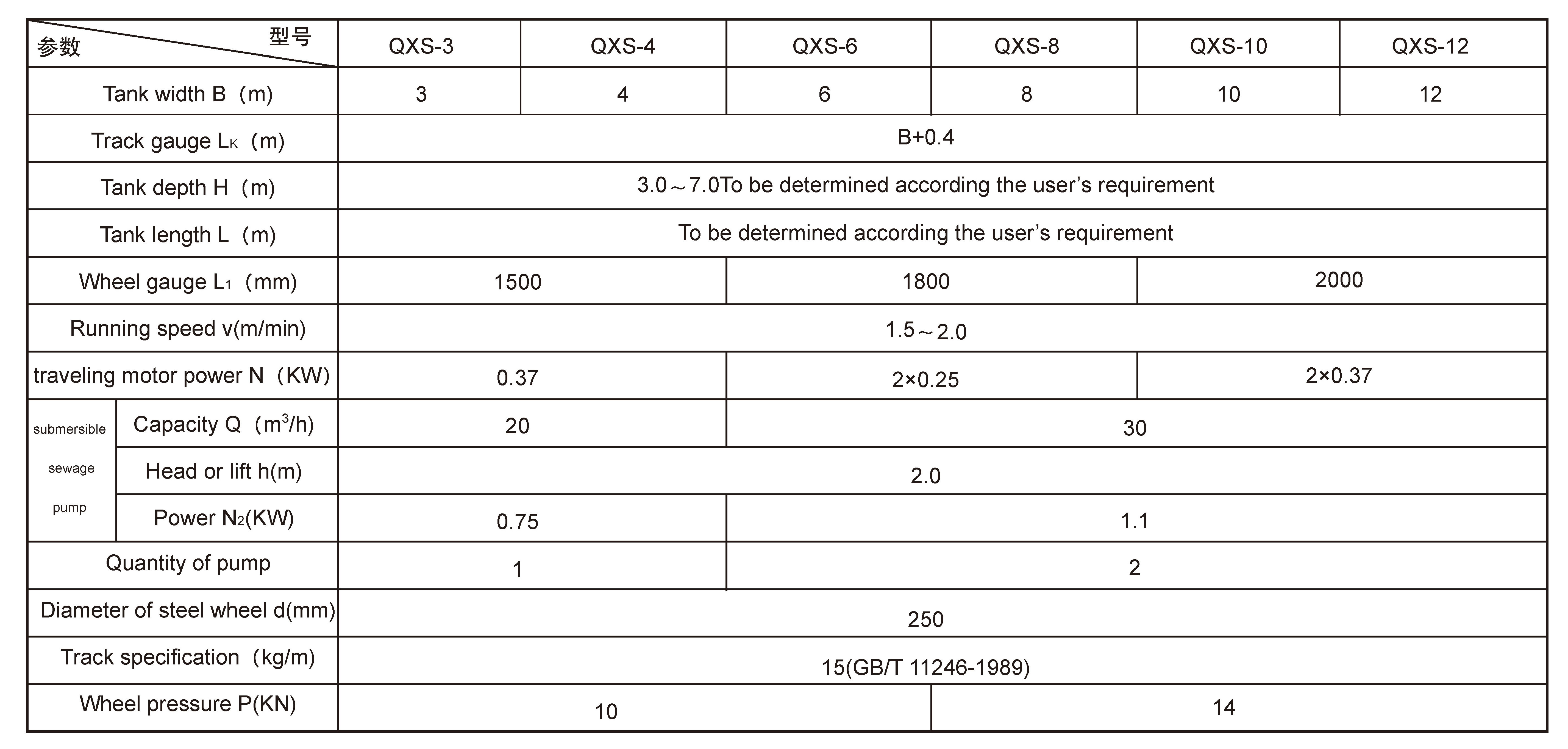

Main technical parameter & installation dimension form

Main fearture

1、Back-and-forth sand suction and skimming,High efficiency and simple structure.

2.The vorex suhmersible pump withlow head sucks the sand wihout waler introducton operation clogging and with abrasion-resistance and safet as well as reia ilty

3. Unidirectional skimming and clean tank surface.

4.The setied sand is hrough erted circumfuence.Tthe organic substance on the sand partile has been dleaned of and the discharged sand particle had no odo.

5.The equipment operation is simple and convenient and the equipment operation can be controlled by localremotel control.

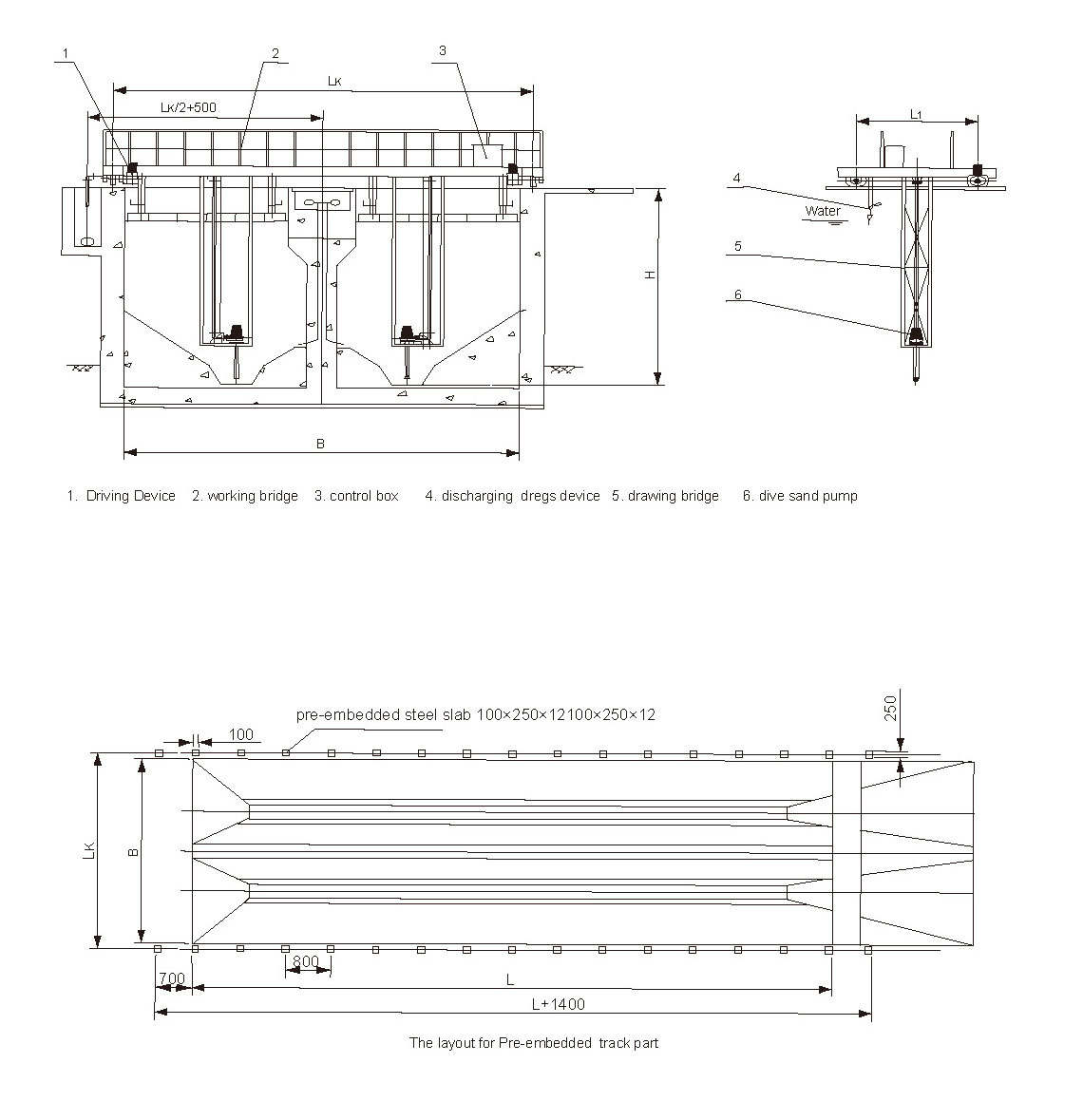

Outline & installation foundation drawing

Recommended products

Product Consultation