ST self-cleaning filyer

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

ST self-cleaning filyer

Category:

Introduction

A set of automatic rinsing brushes are installed with the filter, and themotor drives the brushes rotate.Filter screen is filtered in accordance withdifferent requirements. The self-cleaning is generated by pressuredifference signal and time.

Structure model: vertical, horizontal, on-line structure.

Rinsing

When the pressure difference of inlet and outlet reaches the presetvalue-0.5bar, the self-cleaning process is generated.There are two stepsof self-cleaning process:Start the membrane filter draining valve on theupper cover; the stainless steel brushes rotate driven by the motor,theimpurities trapped on the screen are brushed down and then dischargedout from the draining valve. It takes about 15-30 seconds to self-cleaningwithout stopping. The entire operation process of the filter is controlled byan attached control box.

Rinsing steps

1、When the pressure switch detects the preset valve(0.5bar) betweeninternal and external of the filter screen.

2、Starting the septum draining valve to atmosphere.

3.The motor drives the steel brushes in filter screen to rotate.

4、Starting the septum draining valve.

Control system

lt takes industrial single chip PLC to control automatically which language is Chinese. The backwash can be controlled by pressure diference or preset time. Moreover, t can wash manually and forcibly, even without electricity supply. Filter frequency, washing time, operation signal, rinsing signal, fault signal output as well as communication signal can be set currently

Material

1. Filter shell: carbon steel coated with epoxy(stainless steel will be fittedin accordance with different requirements).

2. Filter screen: stainless steel

3. Rinsing unit: stainless steel

4. Draining valve: casted iron

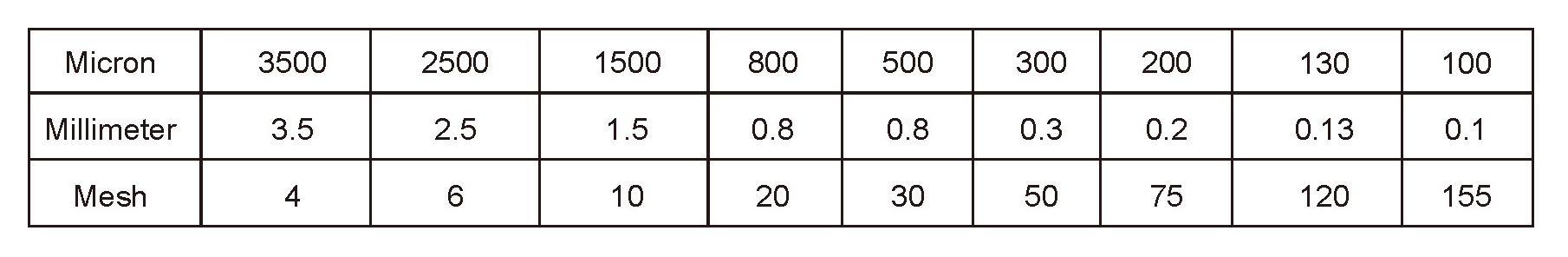

Standard filter grade

Application range

1、Cooling water reatment——-cooling tower.supplement water system, air conditioning system, DC water fiter system,reduce precipitation in heat exchangerand keep its cooling state.

2、Raw waer treatment——can be used to remove sand ,foating solids,algae and organisoms in surface water lake water,sea waler ,resenvoir water,well wateras well as underground water.

3、Industial cyding water——can be used infollowing devices which have certain requirements o water, cooling tower,frlling mill conticaster,polisher, walerpump, magnetic valve, ion exchanger, sprayer, heat exchanger as well as draining pipeline.

4、lIrigation——partcularly suitable for water with high flow capacity and high imnpurities contaning as wellas agicultural irigation,sprinking inigation.park grfcourse and turf irrigation.

5、Papermaking industry———whitewater filtration.

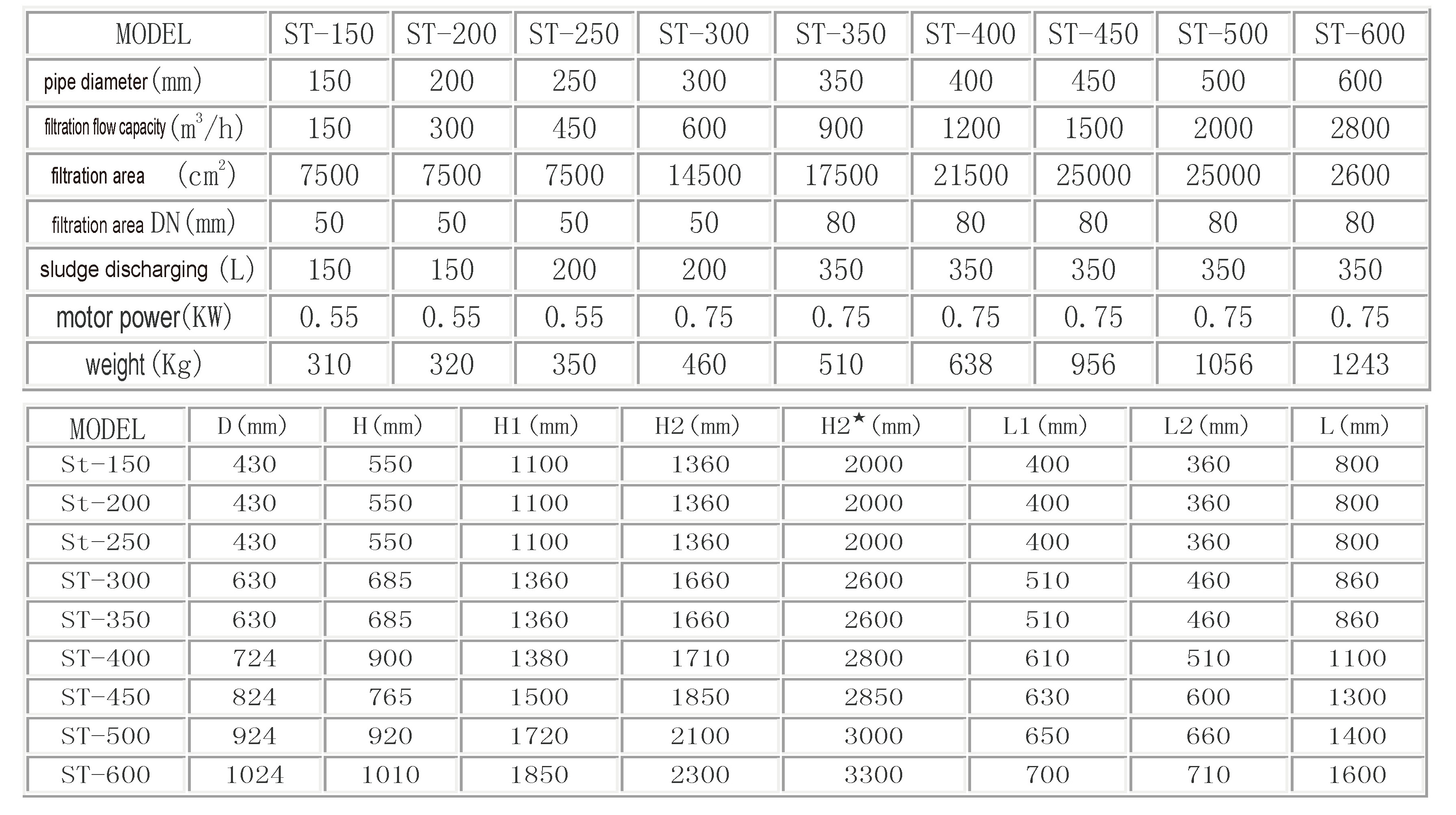

Technical properties

Flow capacity of single set 150-2800mIh,severalsngle set can be inegrated to meet larger fiow capacty.Mlimimal operatio pressure: 0.2mpaMaximum operationpressure:1.0-1.6mpa Highest working temperatre: 75 ℃.Filtaion precision: 3-3500pm.Conrol method: pressure diference, time and manual.Rinsin time. 20-60seconds.Rotary speed of insing stucture: 14-20mpm Pressure loss ofinsing.0.01-0.8mpa Controling voltag.AC 2V;Worcing oliag .threephase 3804.50HZ;LCD interface, humanized designing, simple operation

Technical data and outline

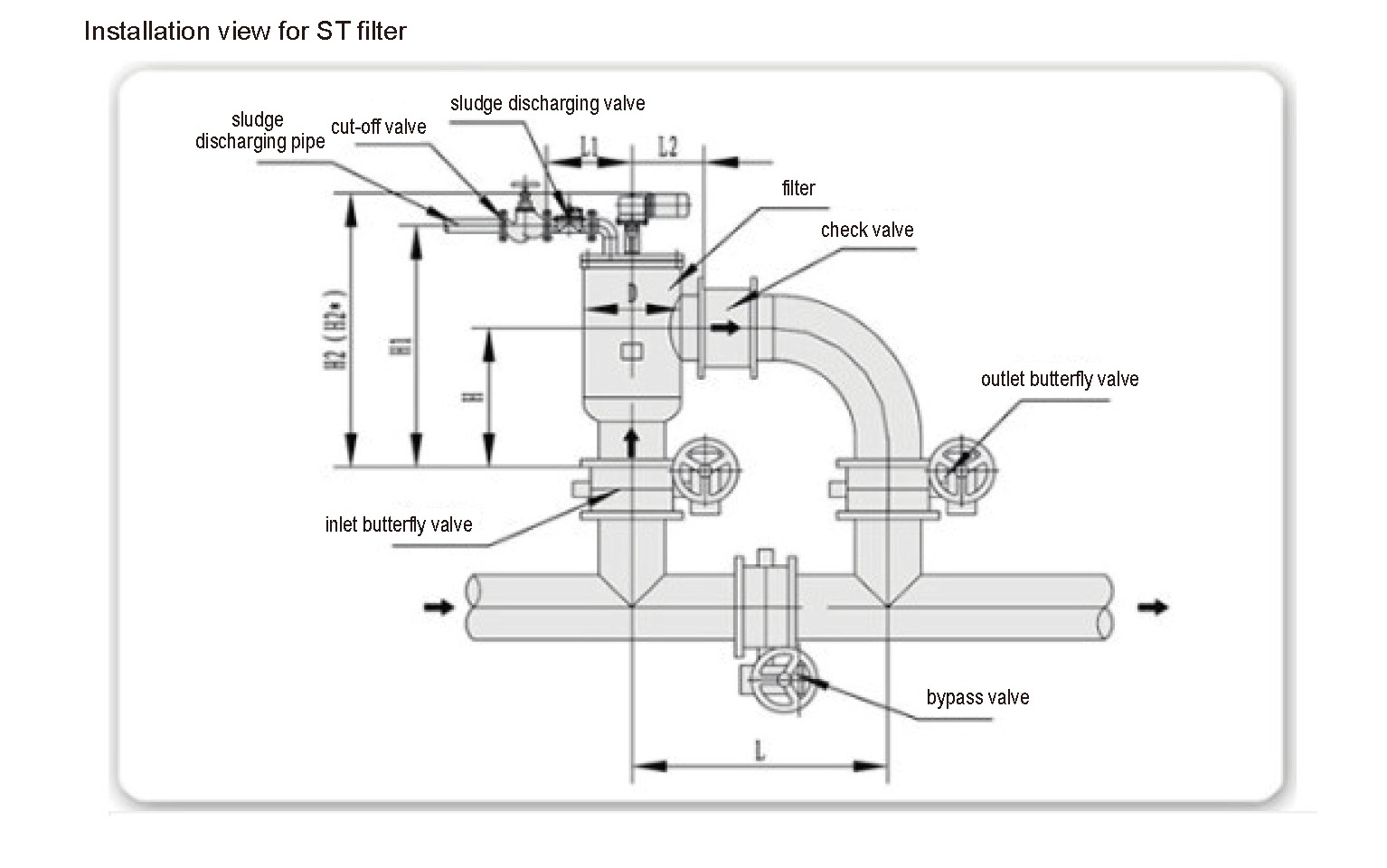

Installation view for ST filter

Previous

Recommended products

Product Consultation