YQG bridge sludge scraper

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

YQG bridge sludge scraper

Purpose

YQG bridge sludge scraper is mainly used for sludge discharge from horizontal-flow sedimentation tank in the town sewagetreatment plant and waterworks. This machine is unidirectional sludge scraping.As per the client's requirement, the aditional skimmercan be installed.

2、Structure & working principle

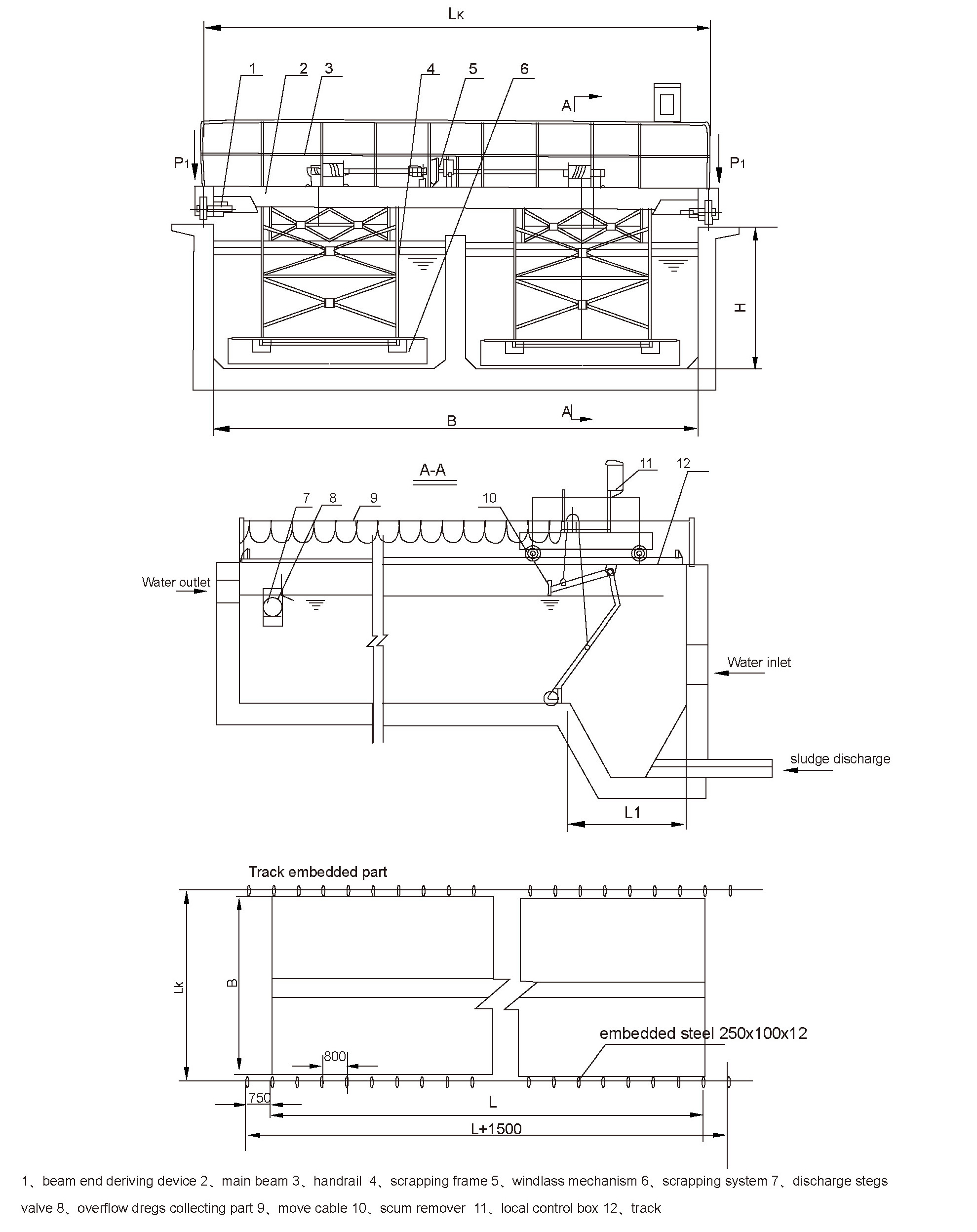

This equipment is of movable bridge type.When the sewage scraper does operate, itstops at the water inlet end.Vhen the sludgescraper operates, the crane lfts down the skimming plate at first while the sludge scraper travels downstream to scrape and collect thescum and skim it in the steel-made skimming chute at the tank end as well as the sludge scraping plate is lifed from the tank bottom.While traveling in opposite direction, the sludge scraping plate is laid down to scrape the sudge at the tank bottom in the sludge collect.ing chute at the tank end and the skimming plate is lited up to leave the liquid level to prevent the scum from traveling in oppositedirection. The back-and-forth operation motion is caried out and thus the sludge scraping and skimming purpose is reached.

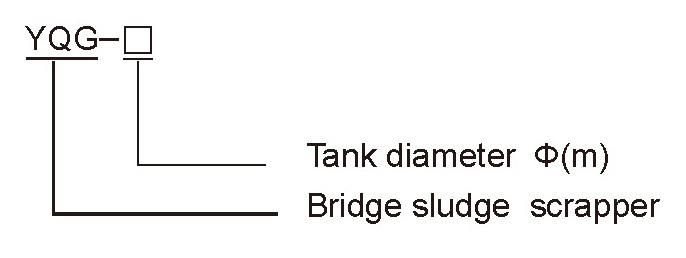

Model explanation

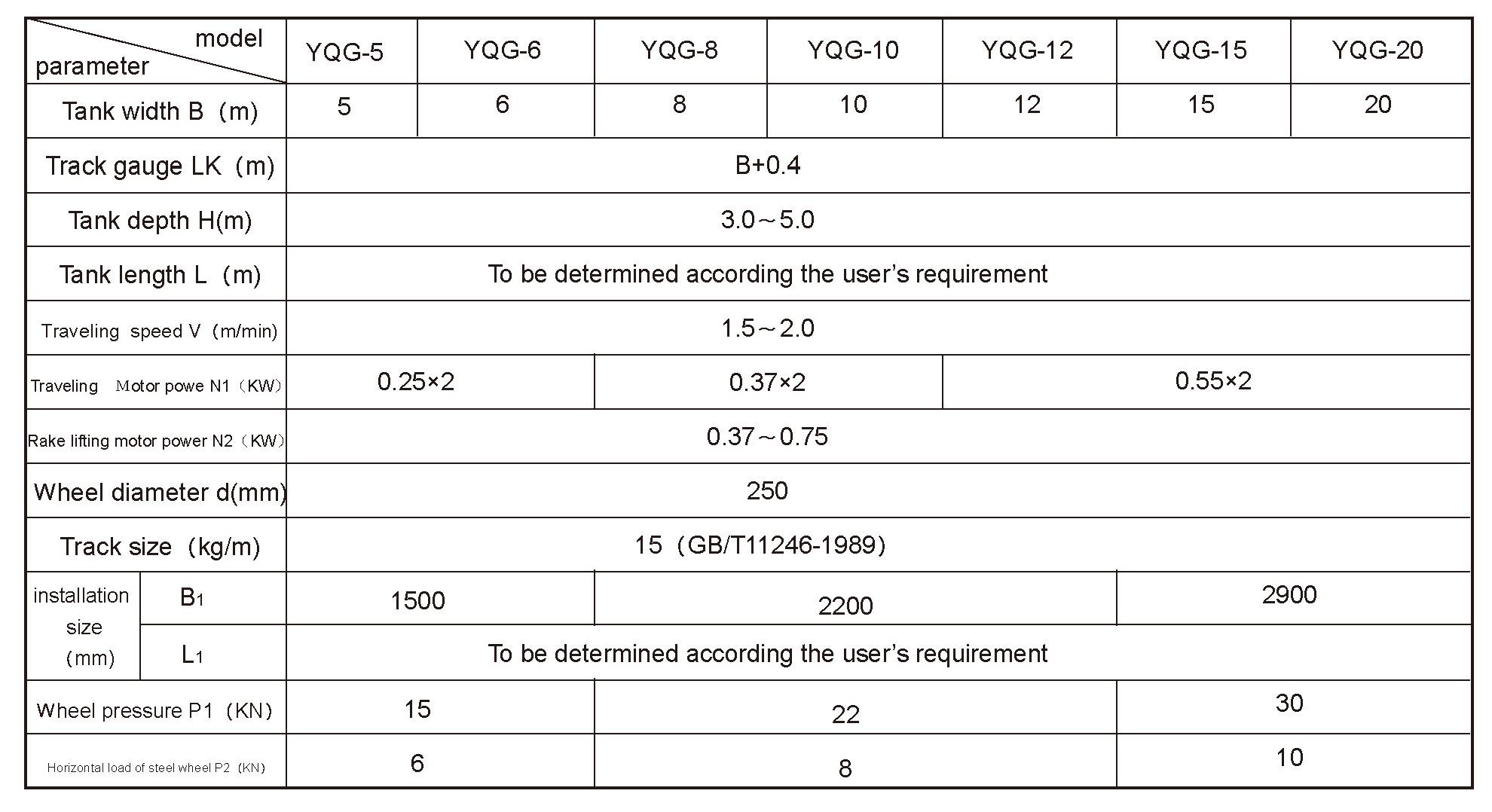

Main technical parameter & installation dimension form

Main feature

1.Both-side drive, both-side roll synchronous drive, smooth operation

2.For traveling above water,the steel wheel traveling is adopted. For underwater scraping plate, the rubber roll traveling is adopted.

3.Skimming operates is opposite way with sludge scraping.

4.The equipment operation is simple and convenient and the equipment operation can be controlled by local remote control.

Outline & installation foundation drawing

Recommended products

Product Consultation