PLS-R50 microfiltration filter control box

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

PLS-R50 microfiltration filter control box

Category:

Product Overview

PLS-R precision filter is a precision machine that uses gravity or pressure difference to make suspended solids pass through a porous medium, trapping solid particles, and achieving effective separation of solid and liquid in the suspension. The filter medium is a porous solid substance used to retain solid particles and permeate liquids during filtration. Based on the function and usage environment of the filtering medium

Equipment Advantages

1. Long service life of the filter: The filter can be used for up to 3 years

2. Convenient filter replacement: Independent mesh, which can be removed independently without affecting other filters

3. Strong impact load resistance: The equipment can operate normally when the inlet SS is not higher than 40mg/L

4. Filtration can operate continuously for backwashing without affecting each other.

5. Small head loss: The head loss is less than 30cm.

6. Good treatment effect: The inlet water quality SS is less than 20mg/L, and the outlet water quality SS is less than 10mg/L

7. Operate fully automatic control.

8. Small footprint: under the same treatment water volume. The floor area of drum filtration equipment is much smaller than that of other filtration process equipment.

9. Low flushing water consumption: Impurities are not easily accumulated on the filter screen, and backwashing high-pressure water can easily remove impurities. The water used is taken from filtered water, with a water consumption of 0.3% of the treated water, which is much lower than the water consumption of other similar filters by 3% to 5%. Reduce the burden of post treatment of backwashing wastewater.

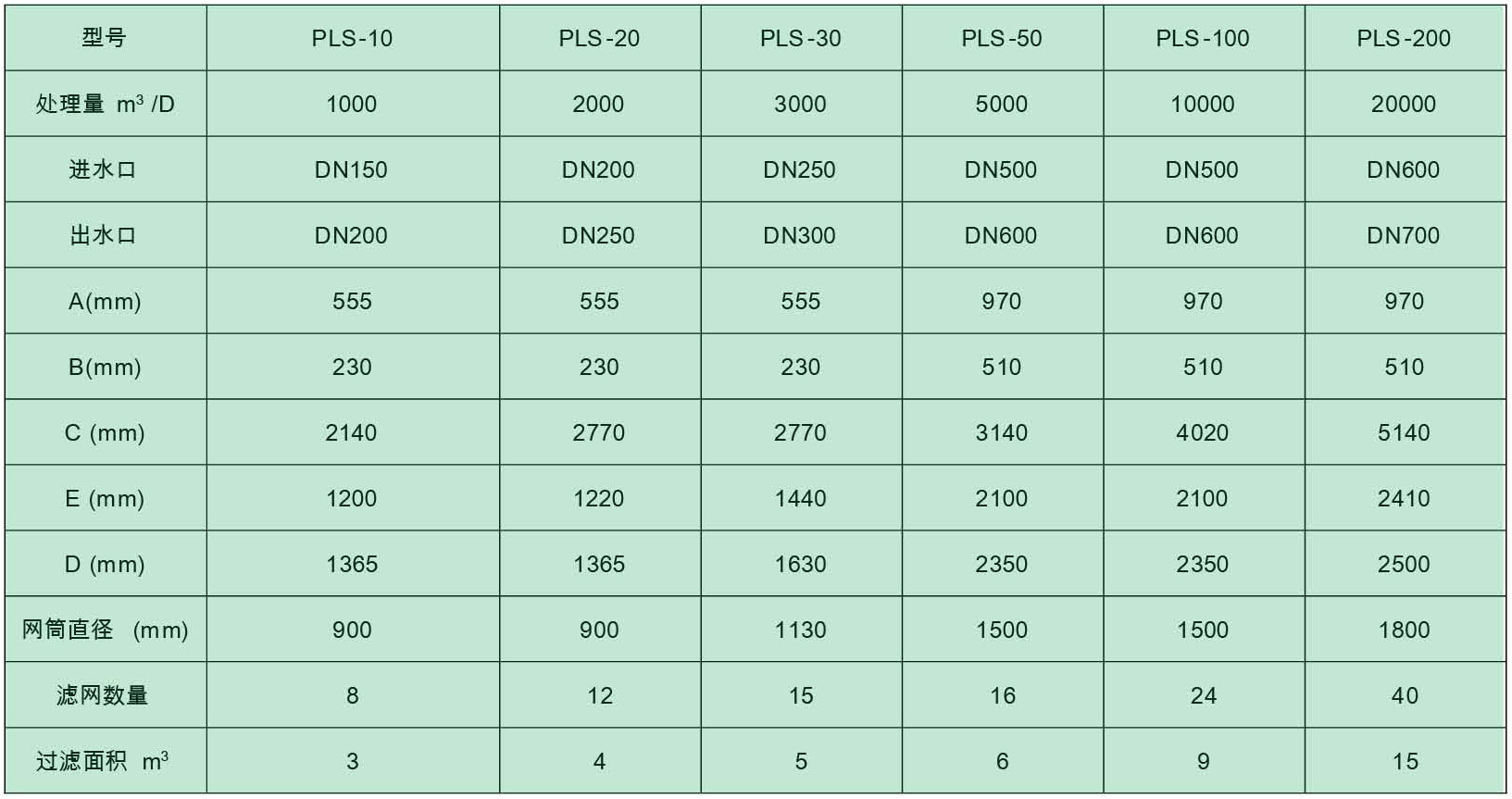

Main technical parameters

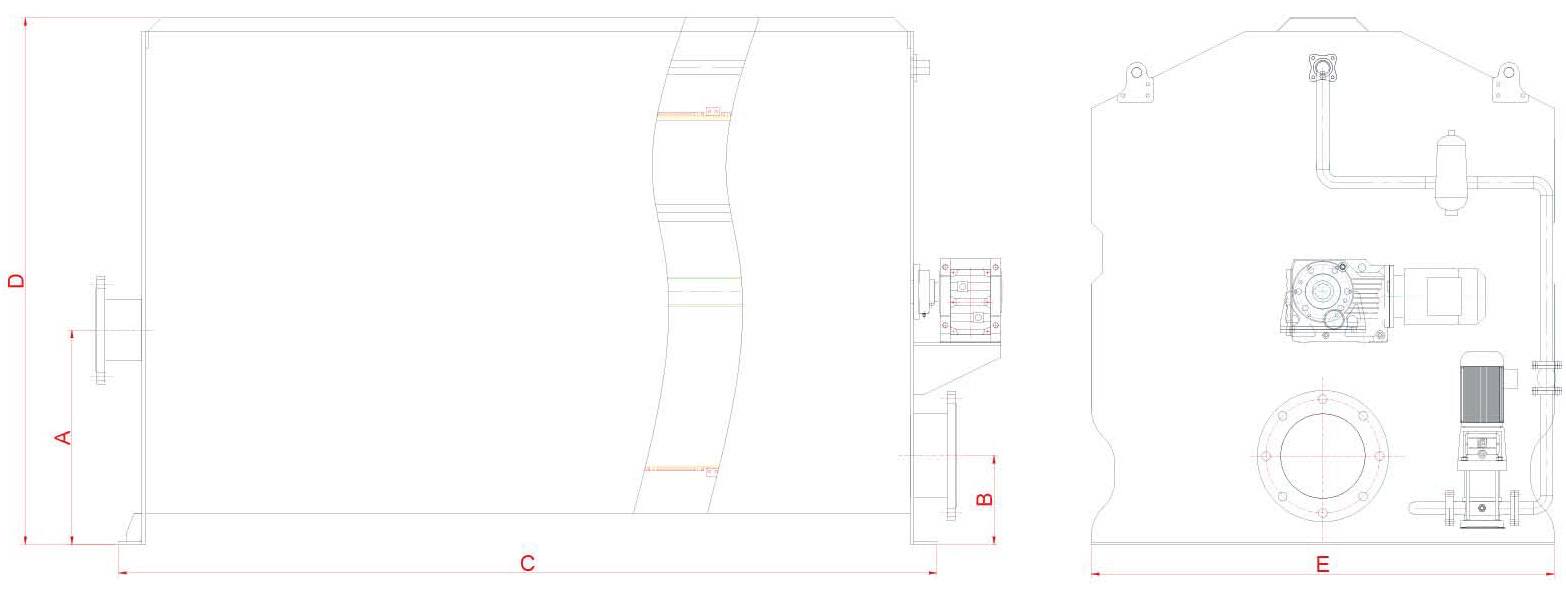

Outline Installation Dimensional Drawing

Recommended products

Product Consultation