BDY inverted-umbrella surface aerator

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

BDY inverted-umbrella surface aerator

Category:

Purpose

BDY inverted-umbrella surface aerator has advantages of reasonable layout,small areacovering, simple installation, convenient maintenance as well as reliable operation.Meanwhile, themotor is not susceptible to be corroded by sewage or waste gas. The gear and bearing aredesigned to be more than 10 years lifespan. ln particular, the advanced mechanical shaft floatingstructure is adopted in coupling of gearbox output shaft and inverted-umbrella shaft which mayrealize the automatic aligning.Ilt also avoids vibration of eccentric moment generated by rotation ofimpeller, and the output shaft is not subjected to the axial and radial force transferred by the impel-ler, thus prolong the lifespan of the integral device. lt is an innovative structure which is differentfrom vertical aerator domestically and abroad.The impeller geometry parameter is designed inaccordance with optimal data concluded by hydraulic model test in lab and reality. It has advan-tages of abundant oxygenation capacity, strong plug flow and easy to mix.The impeller may rotateforward and backward without sticking. Users can control speed of the impeller by double-speedmotor or converter to keep it in the most energy-saving state.BDY inverted-umbrella surfaceaerator is efficient,energy-saving and environmental which technical parameter and economicindex is the same as advanced level of international similar products.

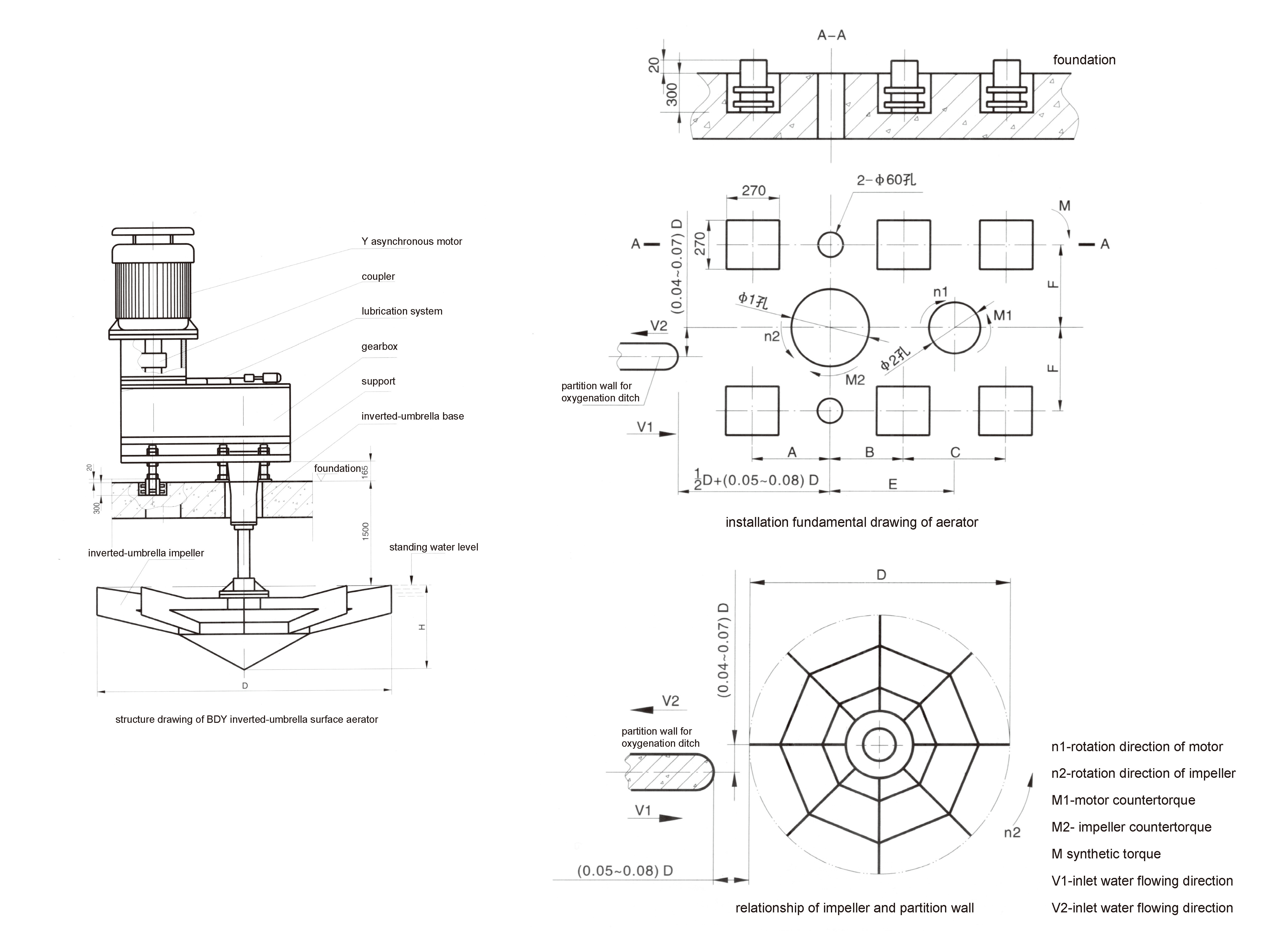

working principle

BDY inverted-umbrella surface aerator consists of motor,coupler,gearbox,lubricating passage,racks,umbrella support,inverted-umbrella impeller and etc.lmpeller rotates, throw water peripherally into air, and then the air is dispersed into finebubbles and totally mixed with the sewage. Oxygen in air dissolves and scatters insewage, then flows forward in form of circular spiral to prevent the sludge precipitatingon the bottom. Biochemical reaction is produced after oxygenation to sewage, and thewater is purified.

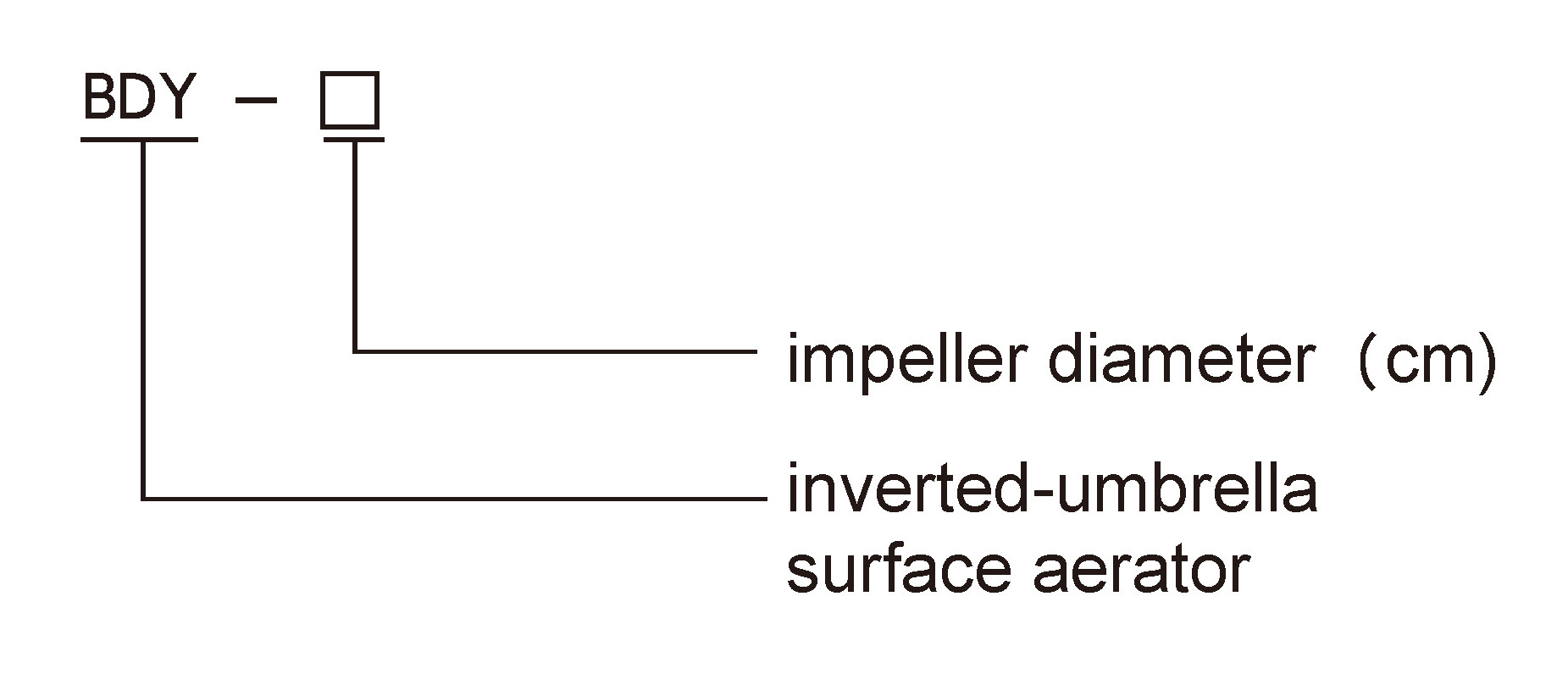

model explanation

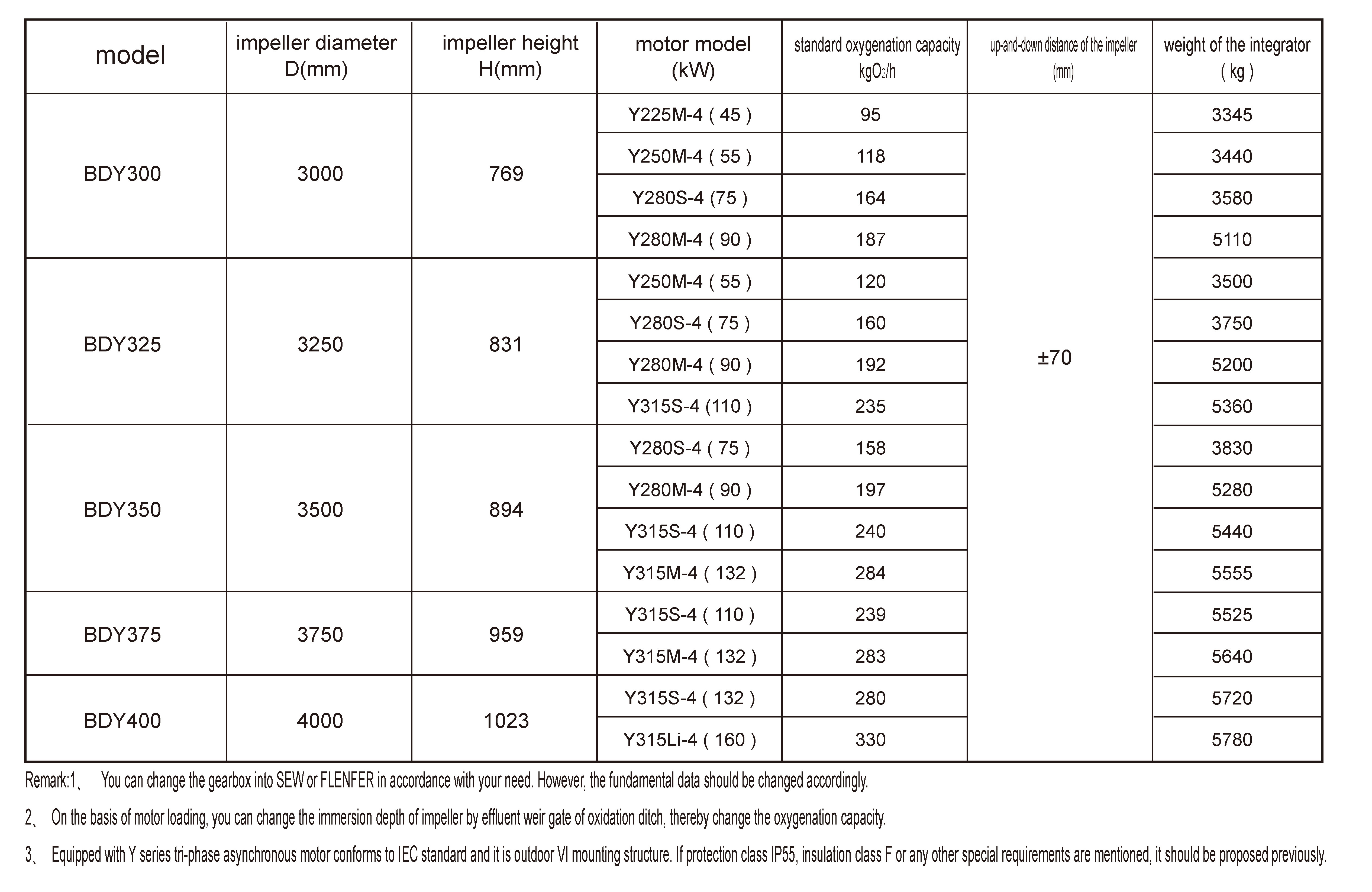

Main technical data and installation dimension

Main characteristics

1、It adopts vertical layout and covers small foor area.The motor is mounted above the gearbox to prevent it being eroded by splashing sewage and waste gas. Easy to install, disassemble and maintain.

2、Vertical gearbox.The gear is carburized with superior low-carbon alloy steel. The gear surface is hardened by grinding.The gearhas advantages of high accuracy, smooth operation, high transmission efficiency and it is designed to be over decade lfespan.ltshould be particularly mentioned that there will be abnormal noise caused by pitting fatigue when the gearbox rotates along a fixeddirection for a long time. lf it happens, you just want to adjust the installation position of gearbox in oxidation ditch and change thedirection of input shaft to convert the non-working touchless gear surface into working gear surface, then the gearbox can be put intonormal operation, furthermore, its working life will be doubled.Moreover, it is easy to disassemble and instal you can just only move the gearbox in opposite direction without changing any other part.

3、The impeller geometry parameter is designed in accordance with optimal data concluded by hydraulic model test in lab and reaitylt has advantages of abundant oxygenation capacity, strong plug flow and easy to mix.The impeller may rotate forward and backwardwithout sticking.

4、Simple structure, reliable, easy to install.

5、Advanced mechanical shaft foating structure is adopted in coupling of gearbox output shaft and inverted-umbrella shaft which mayrealize the automatic aligning. It also avoids vibration of eccentric moment generated by rotation of impeller, and the output shaft is notsubjected to the axial and radial force transferred by the impeller, thus prolong the lifespan of the integral device.

6、Theuser can adopt two-speed motor orconverter to adjust the impeller speed to achieveenergy efficient operation in accordance-with environmental changes and differentneedsof oxygenationcapacity.Brush aerator load volume and oxygenation capacity can beadjusted by changing the weir brushing immersion depth.

outline and installation dimension

Previous

Recommended products

Product Consultation