CF rotary solid-liquid separator

The experimental center has complete equipment, which can perform trace and complete analysis of pollutants, and also has simulated operating conditions such as physicochemical, biochemical, and advanced treatment. The company can customize and manufacture equipment for customers, as well as provide guarantees for their later operation and debugging.

Key words:

CF rotary solid-liquid separator

Category:

Application

CF rotary solid-liquid separator is a advanced solid-liquid separation equipment, it is mainly applied in cities and towns waste water treatment, housing district waste water pretreatment, municipal pump station, tap water plant and etc.

Structure and principle

lt takes rotary type, and a certain sequential plough type toothaccording to the water flux assembling to different clearance. consist ottooth of a harrow. When drive svstem drive the tooth chain moving fromdown to upward, the sundries removed by the tooth, and water flowthrough the tooth gap, when the tooth chain move to peak, it changemove direction, and the sundries drop from the chain because of theself-gravity. With the circle of continuous operation, the tooth chain gainthe sundries unceasing, and reach the solid-liquid separating.

Model explanation

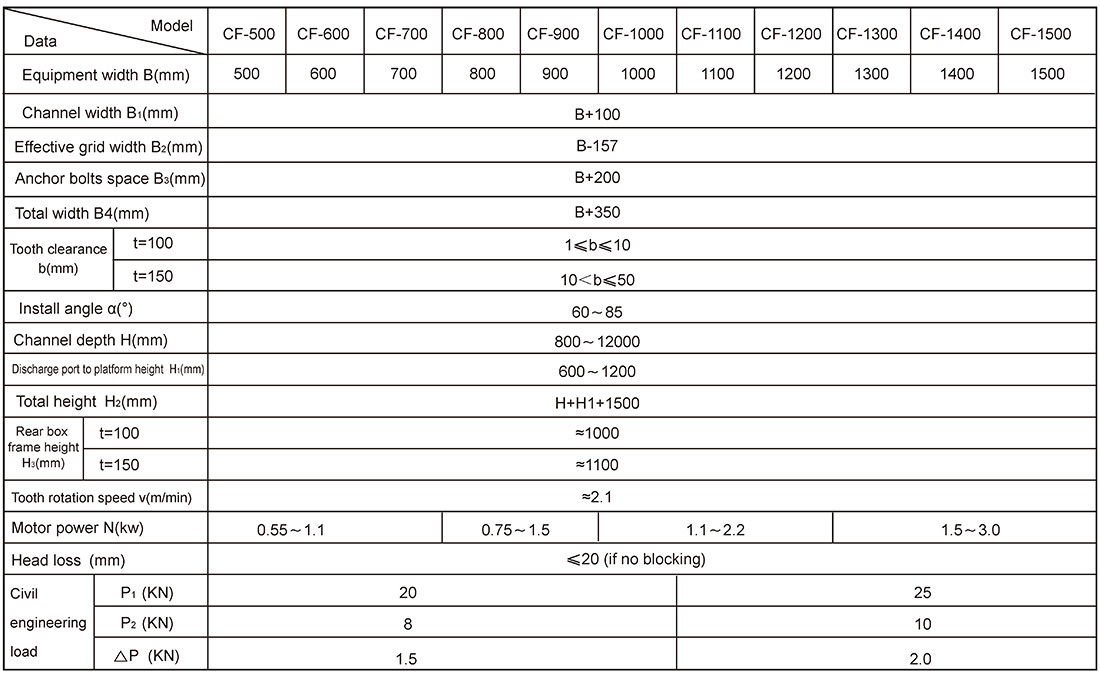

Main technical data and dimension

Main characteristics

1. lt takes cycloid or soiral wheel type reduction gears for drive device. and adoots chain transmission, ow noise, compact structure, running smoothly

2. Frame is integral structure, so it has the advantage of strong rigidity, easy installing and maintenance

3. There are two kinds of tooth of a harrow, for rough screen, the tooth pitch t=150mm, for fine screen, the tooth pitch t=100mm

4. Easy operating, and it can be controlled both local and remote control

5. t has dual protection of mechanical shearing pin and overcurrent to prevent overload, and make the running more smooth

6. when the width of equipment more than 1500mm, it will take inline type to ensure the strength

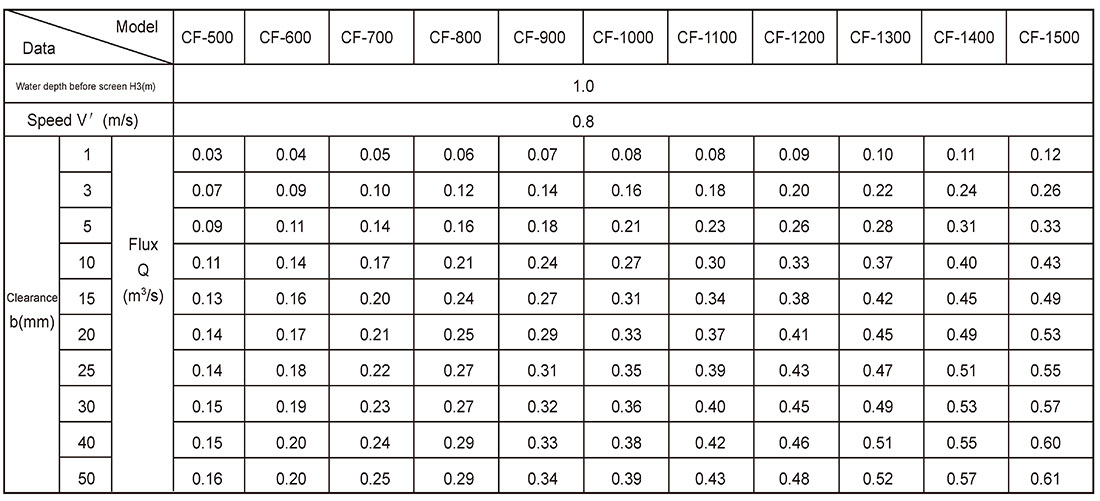

Flux module

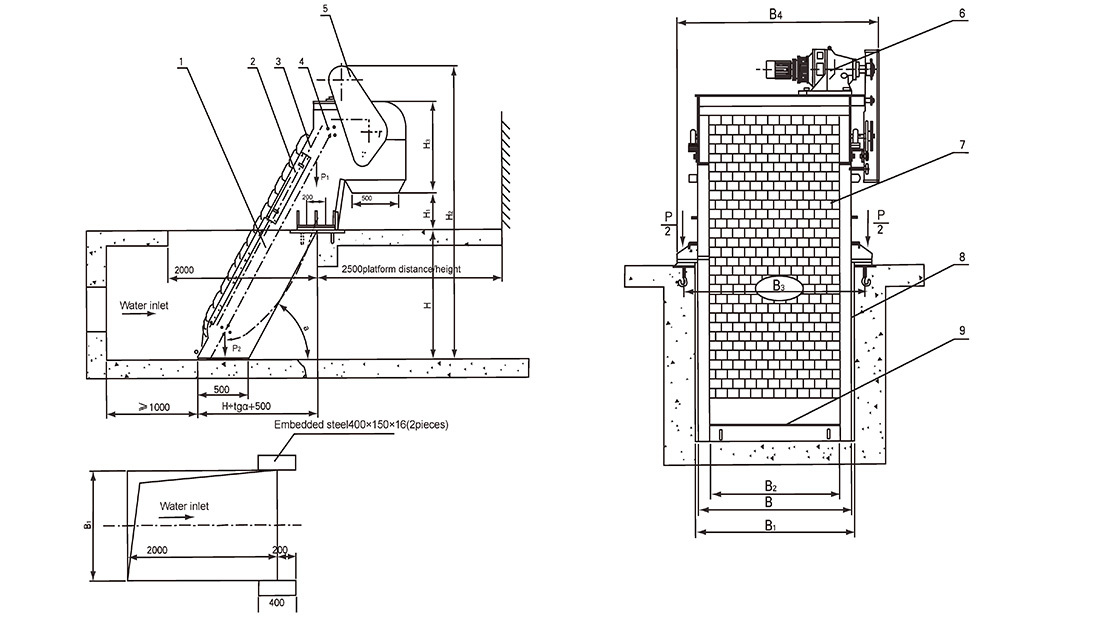

Installation dimension

1.Frame 2.Manhole plate 3.Haulage chain 4.Guide device 5.Motor cover 6.Actuating device 7.Tooth of a harrow 8.Side flap 9.Bottom flap

Previous

Recommended products

Product Consultation